How is motion monitoring used in offshore operations?

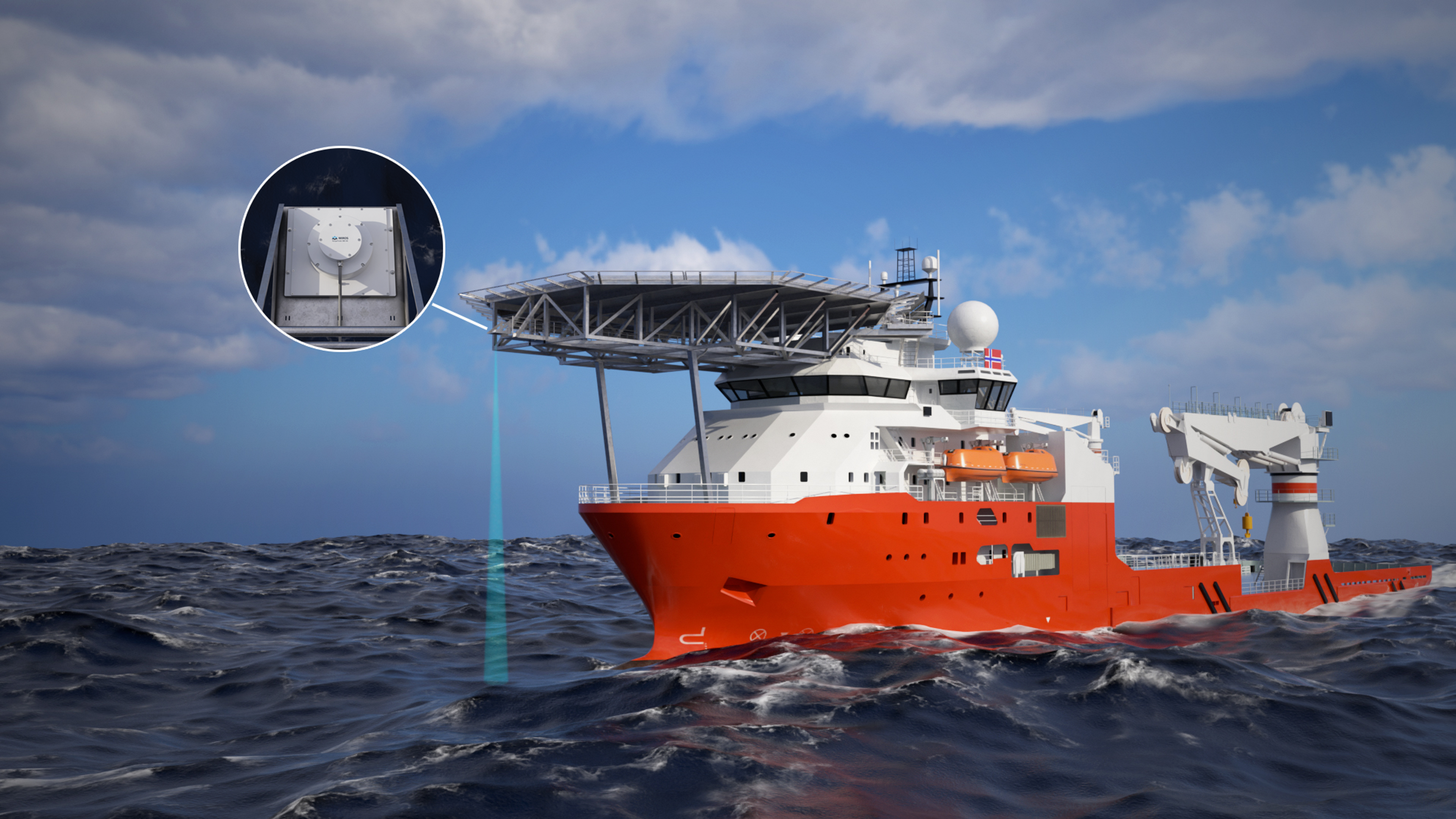

Motion monitoring is fundamental to enhancing safety and operational efficiency in the demanding offshore environment. It involves the precise measurement of vessel, platform, and equipment movements across all six degrees of freedom (6DoF) – Roll, Pitch, Heave, Yaw, Surge, and Sway. High-performance sensors, such as Norwegian Subsea's Motion Reference Units (MRUs), provide the critical real-time data needed for monitoring, control or instrument compensation, ensuring safe personnel and cargo transfers, and optimizing operational windows in challenging sea states.

Our MRUs are integral components in numerous critical offshore applications:

- Dynamic Positioning (DP) systems, mainly used for motion compensation of the GNSS antenna and other position reference systems.

- Active Heave Compensation (AHC) systems utilize MRU inputs to counteract vertical vessel motion, stabilizing cranes, winches, and launch and recovery systems (LARS) for safe and precise lifting operations.

- Gangway, 3D motion compensated gangways require accurate MRUs to motion compensate the vessels movement in-real-time.

- Helideck Monitoring Systems (HMS) employ our sensors to continuously monitor the helideck's motion, providing essential data to ensure safe helicopter landings and takeoffs.

- Wave radar, are used in many offshore operation to know the accurate sea state. This information is then used to optimize the operational windows. OEM versions of Norwegian Subsea MRUs are today included in the world's leading manufacturers of Wave radars. The MRUs provides real-time accurate heave measurements to compensate downward looking wave radars.

- Wind lidar buoyes, High quality wind data requires MRUs for measuring the accurate heave, roll and pitch in Real sea conditions.

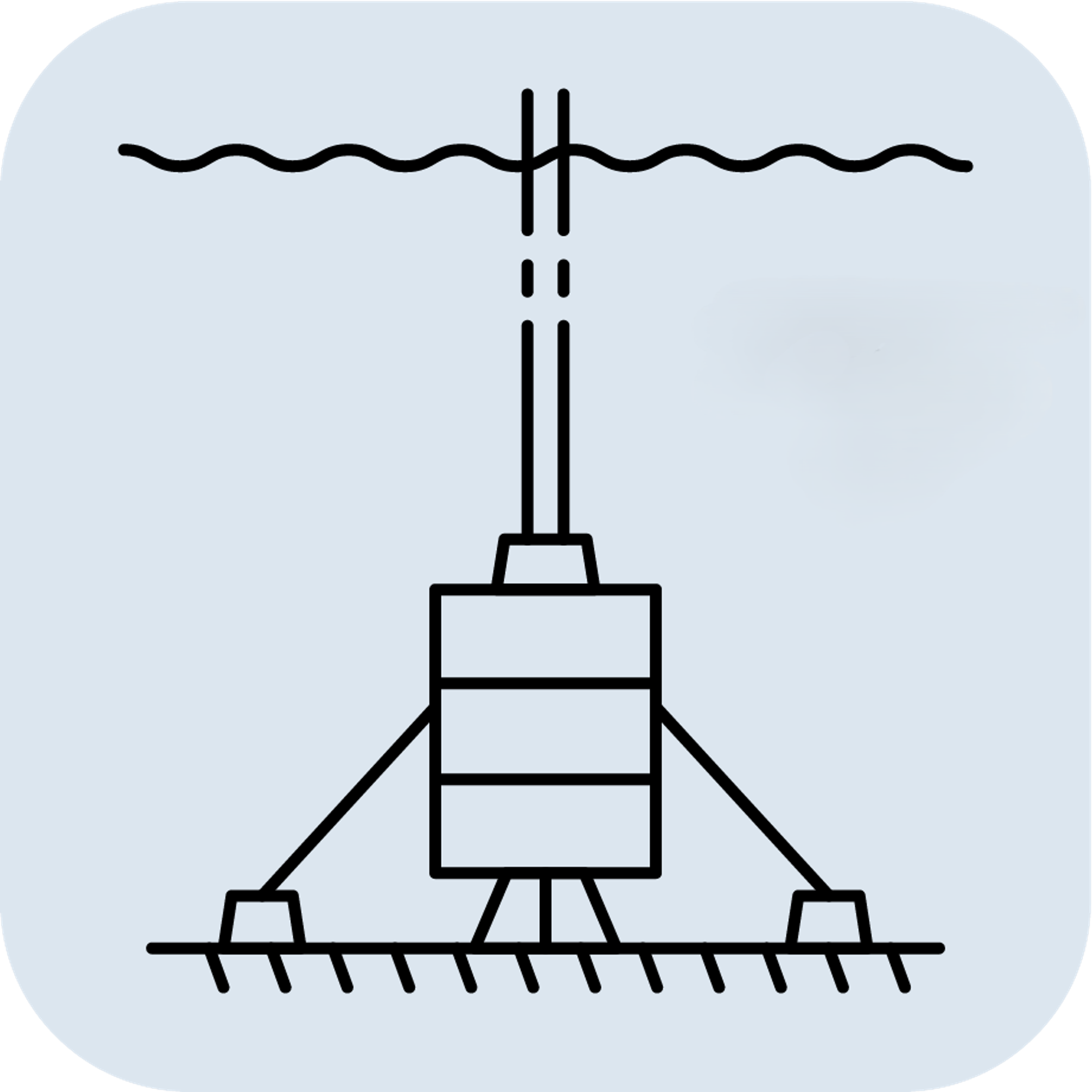

Motion monitoring also extends to subsea operations and the vital task of structural integrity assessment. Norwegian Subsea offers specialized sensors like the MRU Subsea, featuring a robust titanium housing rated for 6000m water depth, ideal for applications such as monitoring the motion of risers and Blowout Preventers (BOPs). Our MRUs are also crucial for guiding Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs) during subsea surveys, installations, and interventions. Additionally, they play a key role in structural health monitoring programs for fixed and floating offshore platforms and wind turbines.

Norwegian Subsea delivers highly accurate, reliable, and cost-effective MRU solutions specifically engineered and validated for the offshore sector. Leveraging state-of-the-art MEMS technology and sophisticated sensor fusion algorithms, our products offer exceptional performance. They are designed for easy integration, supporting a wide range of industry-standard protocols (e.g., UDP, Modbus TCP, Ethernet/IP) and offering flexible connectivity options. Our MRUs are known for their long-term stability, often eliminating the need for recalibration, which reduces lifetime costs, making them ideal for both new projects and as drop-in replacements for retrofitting existing systems.