FAQs

Find the answer to your question here, or contact us at sales@norwegian-subsea.no.

Find the answer to your question here, or contact us at sales@norwegian-subsea.no.

Dutch company Radac is committed to delivering the most advanced wave radar systems that focus on the task of providing accurate, localised wave and seastate data. To support the highest levels of accuracy and reliability, Motion Reference Units (MRUs) from Norwegian Subsea are used as standard in its WaveGuide radar systems. This has helped build an enviable reputation for quality in the offshore industry, with Radac’s systems widely recognised for enabling confident decision-making in diverse and dynamic marine environments.

As the maritime industry accelerates its journey towards smarter, more efficient digital operations, structural health monitoring systems are playing a central role in operational efficiency, safety and sustainability. These systems increasingly depend on real-time, high-fidelity data from Motion Reference Units (MRUs) to contextualise structural stresses with the vessel’s motion in a given sea state. This is especially important in meeting the evolving requirements of classification society SMART notations from bodies such as the American Bureau of Shipping (ABS) and DNV.

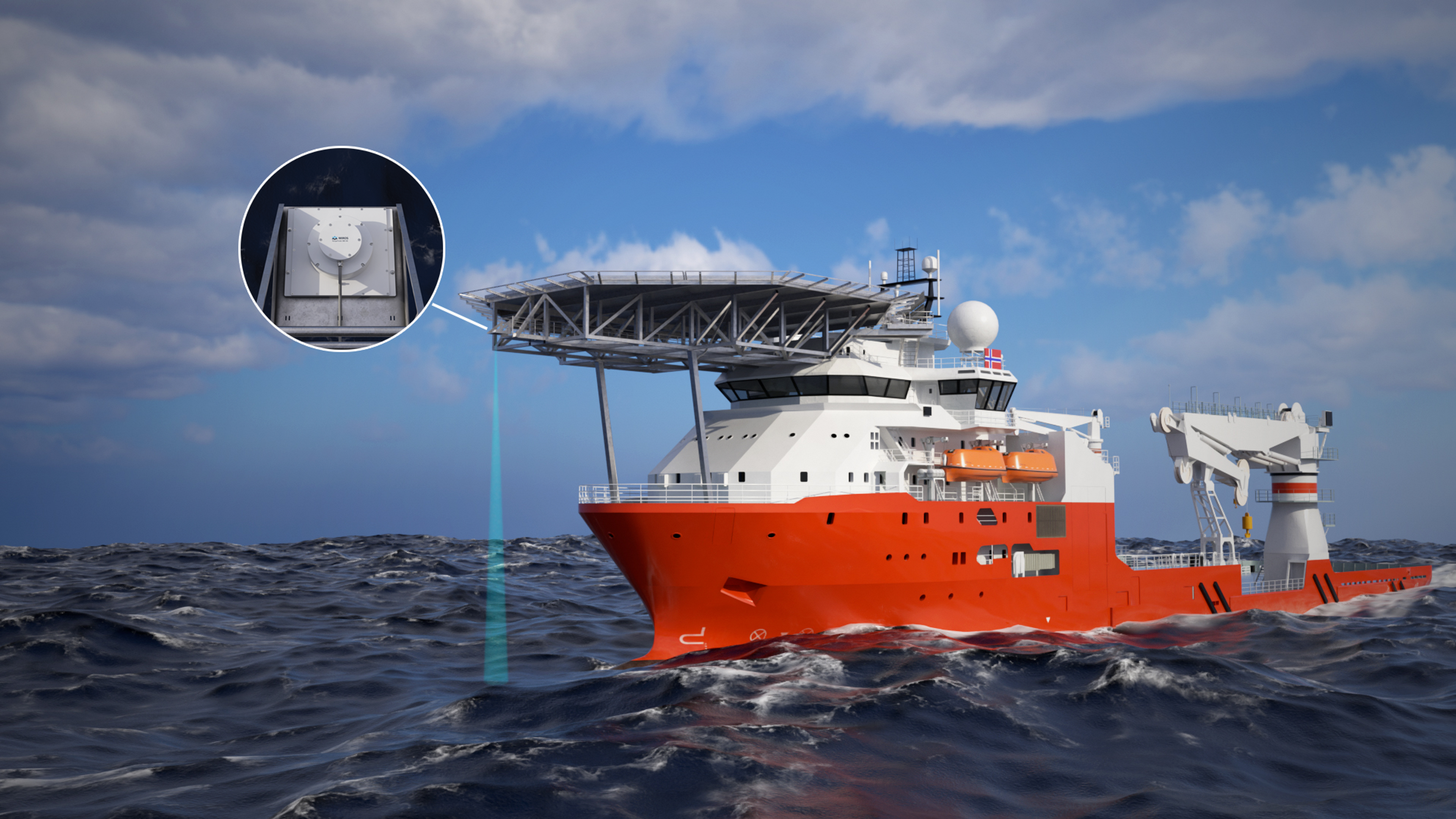

Helideck Motion Monitoring & Weather Data Systems (HMS) provide real-time motion and environmental data essential for flight planning and for pilots to remain in safe control during take off and landing from moving helidecks. The HMS depends on Motion Reference Units (MRU) installed directly on to the support structure that continuously measure the helideck’s movement. Leading HMS manufacturer ShoreConnection chooses MRUs built by Norwegian Subsea.

From bathymetric surveys to subsea inspections and wave radar systems, our Motion Reference Units (MRUs) have been put to work in a wide range of challenging environments during 2025. As the year draws to a close we take a quick look back at some of the highlights, applications, and collaborations that helped shape another strong year of progress for Norwegian Subsea.

Norwegian Subsea has returned from a successful trip to Shanghai, where our compact Motion Reference Units (MRUs) drew strong interest from across the Chinese maritime supply chain during the Marintec China 2025 exhibition. As one of the world’s leading maritime events, Marintec provided an ideal platform to engage with shipbuilders, integrators and equipment manufacturers in a region where innovation and scale go hand in hand.

Next week, the maritime world gathers in Rotterdam for Europort 2025, one of the largest international meeting points for shipbuilders, technology providers and operators. With a strong focus on innovation and sustainability, the exhibition is an important platform for discussing how the industry can meet future demands through smarter, greener solutions.

Yes, Norwegian Subsea MRUs are ideal for wave analysis, providing accurate heave data to determine wave height and period. They integrate easily with wave buoys, lidar, and monitoring systems for real-time sea state analysis.

Yes. An Motion Reference Unit (MRU) provides high-resolution measurements of roll angles, which makes it an effective tool for inclining tests (stability verification / "krengeprøve"). Unlike traditional pendulums, an MRU can deliver accurate data even when the test is carried out at sea under less-than-ideal conditions. By filtering out wave-induced motions and recording precise responses to applied test weights, the MRU improves both accuracy and efficiency of the inclining test.

To improve subsea sensor accuracy, use high-performance MRUs with advanced algorithms and durable housings. Norwegian Subsea MRUs offer 6DoF precision, long-term stability, and easy integration for demanding underwater environments.

When selecting a motion sensor for subsea applications, the right choice combines robust design, deep‑water capability, high accuracy, and ease of integration.

Norwegian Subsea works closely with customers to ensure each sensor is configured to meet specific application needs across marine, subsea, offshore, and industrial environments.

The best Norwegian Subsea MRU is the one that precisely matches your technical needs, environmental conditions, and integration requirements.

ROV motion sensors differ by accuracy, depth rating, and integration ease. Norwegian Subsea’s MRU Subsea offers 6DoF precision, 6000m depth rating, compact design, and proven reliability for underwater navigation and control.

A motion sensor uses MEMS accelerometers and gyros to measure 6DoF movement. Advanced algorithms combine sensor data to deliver accurate, real-time motion tracking for marine and subsea operations.

An IMU measures linear acceleration and angular velocity using accelerometers and gyros. It outputs raw data, unlike an MRU, which uses sensor fusion to provide full 6DoF motion data in real time.

In offshore crane operations, MRUs provide real-time heave data for Active Heave Compensation. This stabilises the load during vessel motion, enhancing safety and efficiency in lifting operations at sea.

A VRU provides accurate roll and pitch data for instrument compensation in dynamic conditions. It's ideal for systems like GNSS antennas or stabilisers where full 6DoF data isn't required, offering a cost-effective solution.

MRUs use advanced filtering algorithms like Kalman filters to remove noise and stabilise motion data. This ensures accurate 6DoF output for critical systems such as DP, AHC, sonar, and gangway control.

Norwegian Subsea’s Motion Reference Units (MRUs) are designed to deliver real-time data through a combination of high-end MEMS sensors, advanced sensor fusion algorithms, and onboard data processing systems.

Motion monitoring measures 6 DoF vessel and equipment movements (Roll, Pitch, Heave, Yaw, Surge, Sway) to maintain safety, effectiveness and asset integrity in offshore oil & gas. Norwegian Subsea MRUs fulfil these requirements.

Motion monitoring ensures safety and efficiency in offshore operations by tracking 6DoF motion. Norwegian Subsea MRUs support key systems like DP, AHC, gangways, HMS, wave radars, and subsea structural monitoring.

Norwegian Subsea MRUs deliver real-time 6DoF motion data via advanced onboard processing. They integrate easily using Ethernet or serial protocols, enabling client systems to perform low-latency analysis for marine and subsea applications.

Deciding whether to rent or purchase a motion reference unit depends on the project duration and frequency of use. Owning the sensor ensures availability when needed and eliminates recurring rental costs.

Key applications include monitoring the dynamic behavior of subsea structures like risers, subsea templates, subsea equipment, installation of bottom fixed structures and Blowout Preventers (BOPs).

Marine motion sensors vary in accuracy, output, and application. From basic inclinometers to advanced MRUs and GNSS/INS systems, each sensor type suits different operational needs based on motion type, precision, and environment.

Error sources can generally be categorized into sensor-intrinsic factors, environmental influences, algorithmic processing limitations, and installation inaccuracies.

Norwegian Subsea offers a range of high-performance Motion Reference Units (MRUs) designed for diverse marine, subsea, and offshore applications. Specifications vary depending on the model required.

A GNSS/INS system combines satellite and inertial data to deliver continuous 6DoF navigation. GNSS corrects INS drift, enabling accurate position, velocity, and orientation—even during signal loss, ideal for precise offshore applications.

A gyrocompass determines true north using gyroscopes and Earth's rotation, not magnetism. It’s essential for heading accuracy in marine and aerial navigation, though performance may vary at extreme latitudes.

A Roll & Pitch sensor provides basic attitude data in dynamic conditions using gyros and accelerometers. It’s more accurate than an inclinometer, but less precise than a VRU or MRU in marine environments.

A VRU is an advanced device that measures the attitude (roll and pitch) of an object using high-end accelerometers and gyroscopes, combined with advanced sensor fusion algorithms. VRUs provide very accurate roll and pitch measurements, even in dynamic environments.

In applications requiring real-time, high-accuracy roll and pitch data the VRU's precise Roll and Pitch data allows control systems to react effectively. For example, motion compensation of GNSS antenna for dynamic positioning (DP-systems), stabilizing fins on vessels or advanced Instrument compensation - Used in monitoring and control systems where only roll and pitch data is needed.

An AHRS provides roll, pitch, and heading using accelerometers, gyros, and magnetometers with sensor fusion. It’s ideal for navigation and control but can be affected by magnetic interference.

An Inclinometer measures static tilt relative to gravity using accelerometers. It’s ideal for stationary applications but not suitable for dynamic environments due to its inability to compensate for motion or vibration.

An IMU outputs raw acceleration and rotation rate data using accelerometers and gyros. It doesn’t provide attitude or position directly, making it ideal for systems with external processing like robotics or navigation.

An Inertial Measurement Unit (IMU) is an electronic device that uses accelerometers and gyroscopes, and sometimes magnetometers, to measure and report an object's linear acceleration and angular velocity.

Norwegian Subsea MRUs use HS/commodity code 9015.80.0000. This globally recognised code classifies products for customs, helping determine import duties, taxes, and any applicable trade regulations.

For Remotely Operated Vehicle (ROV) operations, the Norwegian Subsea MRU Subsea is the ideal solution. Its design specifically caters to the demanding conditions of subsea environments.

A Motion Reference Unit (MRU) or a Vertical Reference Unit (VRU) is an important component in Dynamic Positioning (DP) systems to providing reliable and precise roll and pitch measurements. Norwegian Subsea Motion Reference Units (MRUs) are engineered for high accuracy and reliability, making them excellent choices for Dynamic Positioning (DP) systems. Our MRUs utilize advanced sensor fusion algorithms and state-of-the-art MEMS technology to provide precise 6DoF motion data (Roll, Pitch, Heave, Yaw, Surge, Sway) crucial for motion compensation of GNSS antenna and other position reference systems.

The NORSUB MRU can be configured with industry-standard protocols, enabling easy interfacing with existing DP systems or serving as a replacement for other MRUs/VRUs. The MRU/VRU can be installed in any direction. The configuration software allows for convenient setup of the remote monitoring point, specifically the GNSS antenna location.

To accommodate various installation requirements, the NORSUB MRU can be supplied with either an industrial junction box or a pigtail cable for integration into existing systems. This ensures compatibility and ease of implementation in different vessel setups.

MEMS-based MRUs offer compact, cost-effective, and highly accurate motion sensing. Compared to FOG-based units, they provide excellent performance and reliability for marine applications with easier integration and lower total cost of ownership.

IMUs output raw motion data needing external processing. MRUs, like those from Norwegian Subsea, deliver calibrated, real-time 6DoF motion data using sensor fusion, ideal for direct use in marine and offshore systems.

Motion monitoring is a cornerstone of safety, operational efficiency, and asset protection in the offshore industry: whether on vessels, platforms, or subsea equipment.

Selecting the right motion sensor for use on Remote Operated Vehicles (ROV) is essential, and Norwegian Subsea provides specialised solutions tailored for these needs.

ROV seabed mapping demands accurate motion compensation for sonar. Norwegian Subsea MRUs deliver precise 6DoF motion data, ensuring real-time correction, improved sonar clarity, and reliable mapping.

ROVs use advanced sensors like sonar, cameras, DVLs, and MRUs for navigation, inspection, and data gathering. Norwegian Subsea’s MRUs deliver accurate 6DoF motion data, essential for control and subsea stability.

Norwegian Subsea products are engineered around state-of-the-art Micro-Electro-Mechanical Systems (MEMS) sensor technology. This forms the core of our Motion Reference Units (MRUs) and motion sensors.

We combine these high-quality MEMS sensors with advanced, proprietary sensor fusion algorithms. This sophisticated processing allows us to deliver highly accurate and reliable 6 Degrees of Freedom (6DoF) motion data, including Roll, Pitch, Yaw, Heave, Surge, and Sway, even in challenging dynamic marine environments.

Norwegian Subsea offers the MRU Subsea, a high-accuracy, 6000m-rated motion sensor for subsea use. It provides reliable 6DoF data and integrates easily into ROV, AUV, and subsea monitoring systems.

The MRU Subsea from Norwegian Subsea is the optimal choice for subsea operations, offering 6000m depth rating, high-accuracy 6DoF data, and compact design with easy integration for ROVs, AUVs, and monitoring systems.

The Motion Reference Unit (MRU) monitors vessel motions to evaluate risks related to sloshing and structural fatigue in cargo containment systems. It supports a condition-based inspection regime under DNV’s Alternative Survey Programme (ASP).

MRUs provide accurate roll, pitch, and heave data essential for Helideck Monitoring Systems. This real-time motion data ensures helicopter operations meet safety standards like CAP 437 in dynamic offshore conditions.

Choosing the right MRU depends on installation depth, accuracy, and integration needs. Norwegian Subsea offers models for control rooms to deep-sea use, with flexible outputs, accuracy tiers, and connector options for diverse applications.

Yes, the MRU supports heave output (position, velocity, acceleration) at two remote points, plus a third at the vessel's centre of gravity. This allows one MRU to serve multiple applications, like heave-compensated winches.

The MRU Marine offers multiple connection options using a 16-wire Lemo cable. Choose between a pigtail cable, Junction Box V2 with external connectors, or IP-68-rated Junction Box V3 with internal terminals and analogue outputs.

Motion Reference Units (MRUs) are essential components in offshore wind turbines, providing precise measurements of the structure's motion across all six degrees of freedom (Roll, Pitch, Heave, Yaw, Surge, Sway). Norwegian Subsea MRUs utilize advanced MEMS sensors and sensor fusion algorithms to deliver high-accuracy motion data, crucial for operations in the demanding offshore environment.

This motion data serves two primary purposes. Firstly, it is vital for Structural Health Monitoring (SHM). By continuously tracking the turbine's movements and vibrations, operators can detect potential structural fatigue, assess integrity, ensure safety, and optimize maintenance schedules. Secondly, particularly for floating offshore wind turbines, accurate motion data from the nacelle and platform base is fed into the turbine's control system. This allows for adjustments to blade pitch and nacelle yaw to maximize energy generation efficiency and stability despite wave and wind-induced motion.

To purchase Norwegian Subsea MRUs, fill out the "Request a quote" form or contact sales directly. Our team will help tailor a sensor solution to meet your technical and operational requirements.

MRU dimensions vary by model: Compact, Marine, Subsea, Ex, and OEM (on request). Each has a different size and weight suited for specific environments. See full specs for exact measurements and details.

A Vertical Reference Unit (VRU) is an advanced device that measures the attitude of an object, specifically its Roll and Pitch.

A Motion Reference Unit (MRU) measures six degrees of motion including heave, surge, and sway, while a Vertical Reference Unit (VRU) only outputs roll and pitch. Both use the same hardware and sensor algorithms.

The MRU Marine is IP-68 rated with Lemo connectors and LEDs. The Marine SW supports 50m depth, uses SubConn connectors, and comes in two versions differing by available output combinations.

Yes, the MRU outputs accelerations as well as velocities. You can configure the MRU to output acceleration and velocity data in the MRU, Vessel or NED frame. Both raw and lowpass filtered accelerations are available.

The MRU calibration certificate is valid for four years, but recalibration is rarely needed. Most models maintain specified accuracy for their lifetime, especially when selecting higher-precision series like the 6000 or 9000.

Yes, our MRUs measure surge and sway as oscillatory motions around a zero-mean position. For high-precision applications like 3D motion compensation, we recommend the 9000 series due to its superior roll/pitch accuracy.

All Norwegian Subsea Motion Reference Units (MRUs) include Ethernet communication and support the standard Ethernet protocols, as well as passive PoE.

An MRU measures motion in six degrees of freedom using gyroscopes and accelerometers. It provides accurate real-time motion data for marine monitoring, control, and instrument compensation, but cannot track long-period linear displacement.

Mount the MRU near your measurement point and avoid high vibration or elevated positions. Remote measurement is possible, but increases heave error with distance; choosing a higher accuracy model helps reduce this inaccuracy.

To contact Norwegian Subsea, use the "Request a quote" form or reach out via email or phone. Our experts will help you choose the ideal sensor for your application and requirements.

Norwegian Subsea distinguishes itself in the Vertical Reference Unit (VRU) and Motion Reference Unit (MRU) market by delivering high-performance, robust motion sensors that are rigorously tested and validated in real sea conditions, not just laboratory environments. We focus on providing exceptional accuracy (with options like ±0.05°, ±0.02°, and ±0.01° Roll/Pitch accuracy across our series) combined with reliability, ensuring dependable data for critical operations.

A key differentiator is our commitment to cost-effectiveness. Our MRUs offer a highly competitive price point without compromising performance. Furthermore, they are designed for long-term value, typically requiring no recalibration during their operational lifetime for most applications (backed by a 4-year calibration certificate), significantly reducing maintenance costs. This also makes our units ideal for cost-effective retrofitting, often serving as drop-in replacements for older systems.

Norwegian Subsea provides a comprehensive range of high-performance Motion Reference Units (MRUs), often referred to as inertial measurement units (IMUs), designed for demanding marine, subsea, and offshore applications. Our MRUs leverage advanced sensor fusion algorithms and state-of-the-art MEMS sensor technology, rigorously tested and validated in real sea conditions to ensure exceptional accuracy and reliability.

Our MRUs deliver high accuracy across Roll, Pitch, Heave, Surge, Sway, and Yaw (6DoF). We offer different accuracy tiers (±0.05°, ±0.02°, ±0.01° for Roll & Pitch) across our product lines to meet diverse operational requirements and budgets. A key advantage is their long-term stability; our MRUs typically do not require recalibration during their operational lifetime for most applications, reducing maintenance overhead and ensuring consistent performance.

Real-time motion damping systems rely on precise motion measurements to counteract unwanted movements caused by wave action, ensuring stability and operational safety for vessels and platforms. The core component providing these critical measurements is a Motion Reference Unit (MRU).

Norwegian Subsea MRUs utilize advanced MEMS sensors and sophisticated sensor fusion algorithms to accurately measure the vessel's or equipment's motion in all six degrees of freedom (Roll, Pitch, Heave, Yaw, Surge, Sway) in real-time. This high-fidelity motion data is essential for the damping system.

Norwegian Subsea is committed to providing high-performance Motion Reference Units (MRUs) that are also cost-effective. While specific pricing for our MRU Subsea depends on the required accuracy grade (Series 3000, 6000, or 9000) and configuration options, we design our products to offer significant long-term value.

The MRU Subsea features a robust titanium housing rated for 6000 meters water depth, ensuring reliability in demanding subsea environments. Its compact size, ease of integration using standard Ethernet protocols and Subconn connectors, and the fact that it typically requires no recalibration during its operational life contribute to a lower total cost of ownership compared to many alternatives.

Norwegian Subsea MRUs are available in a VRU/Inclinometer version that excludes Heave, Surge, and Sway outputs, while retaining high Roll and Pitch accuracy and performance in dynamic marine conditions.

Norwegian Subsea MRUs support Ethernet communication using UDP, Modbus TCP, and Ethernet/IP protocols. These options ensure seamless integration into marine and industrial systems requiring reliable, real-time motion data transfer.

Norwegian Subsea offers a range of high-performance Motion Reference Units (MRUs) designed for diverse marine, subsea, and offshore applications. All our MRUs utilize advanced sensor fusion algorithms and state-of-the-art MEMS technology, ensuring high accuracy and reliability validated in real sea conditions. They are available in three accuracy tiers based on Roll & Pitch performance: Series 3000 (±0.05°), Series 6000 (±0.02°), and Series 9000 (±0.01°). Standard heave accuracy across applicable models is 5.0 cm or 5.0%. Our MRUs are designed for easy integration with standard protocols (Ethernet UDP, Modbus TCP, Ethernet/IP, NMEA, etc.) and user-friendly web-based configuration software.

Key specifications vary by model:

A Norwegian Subsea Motion Reference Unit (MRU) is an advanced sensor system designed to accurately measure the motion of marine vessels, offshore structures, and subsea equipment in all six degrees of freedom (6DoF): Roll, Pitch, Yaw, Heave, Surge, and Sway. Our MRUs utilize state-of-the-art MEMS (Micro-Electro-Mechanical Systems) sensor technology combined with sophisticated sensor fusion algorithms to deliver precise and reliable motion data.

Norwegian Subsea MRUs are engineered for high performance and robustness, rigorously tested and validated in real sea conditions to ensure accuracy and dependability. We offer various accuracy levels across our product series (±0.05° for Series 3000, ±0.02° for Series 6000, and ±0.01° for Series 9000 Roll & Pitch), meeting diverse operational requirements. A key benefit is their long-term stability; our MRUs typically do not require recalibration during their operational lifetime for most applications, reducing maintenance needs and costs.

Inclinometers offer basic static tilt readings, Roll & Pitch Sensors suit moderate motion, while VRUs provide precise roll and pitch in dynamic conditions. Choose based on motion complexity, accuracy needs, and budget.

Thank you for your inquiry regarding pricing for Motion Reference Units (MRUs) suitable for Remotely Operated Vehicle (ROV) operations. Norwegian Subsea offers the MRU Subsea, specifically designed for demanding subsea applications like ROV and AUV integration. Its key features include a robust titanium housing depth-rated to 6000 meters, a compact footprint for easy installation, and reliable Subconn connectors for seamless interfacing.

The MRU Subsea provides high-accuracy motion data (Roll, Pitch, Heave, Yaw, Surge, Sway) crucial for precise ROV control and navigation. Pricing for the MRU Subsea varies depending on the specific configuration required, primarily the selected Roll & Pitch accuracy level (±0.05° for Series 3000, ±0.02° for Series 6000, or ±0.01° for Series 9000) and any optional features such as Magnetic Heading.

Norwegian Subsea offers the MRU Subsea, specifically engineered for demanding subsea monitoring applications. This high-performance sensor features a robust titanium housing depth-rated to 6000 meters, ensuring reliable operation in deep-water environments. Its compact size and small footprint facilitate easy installation on various subsea structures and vehicles.

The MRU Subsea delivers exceptional accuracy, available in Series 3000 (±0.05°), 6000 (±0.02°), and 9000 (±0.01°) for Roll and Pitch measurements, with a heave accuracy of 5.0 cm or 5.0%. Interfacing is straightforward thanks to the industry-standard 8-pin Subconn wet-mateable connector and support for Ethernet (UDP, Modbus TCP, Ethernet/IP) and serial (RS-232/RS-485) communication protocols. Like all our sensors, it can be mounted in any orientation.

Norwegian Subsea is a leading global supplier of high-performance motion sensors, including Vertical Reference Units (VRUs), specifically designed and validated for the demanding conditions of the offshore industry. Our sensors utilize advanced algorithms and state-of-the-art MEMS technology to deliver reliable and accurate attitude data (Roll and Pitch).

All our Motion Reference Unit (MRU) models – the MRU Compact (IP65), MRU Marine (IP68/50m), MRU Subsea (6000m Titanium), and MRU Ex (Hazardous Areas) – are available in a dedicated Inclinometer/VRU version. These VRU versions provide the same exceptional Roll and Pitch accuracy (ranging from ±0.05° to ±0.01° depending on the series) as our full MRUs, even in irregular coupled motions, but without Heave, Surge, and Sway outputs.

Motion Reference Units (MRUs) are essential components in Remotely Operated Vehicle (ROV) operations because they provide precise, real-time measurements of the vehicle's motion in all six degrees of freedom (Roll, Pitch, Yaw, Heave, Surge, Sway). This data is critical for accurate navigation, positioning, and control of the ROV in the dynamic subsea environment.

The high-accuracy motion data supplied by an MRU allows the ROV's control system to compensate for wave-induced motion and currents, ensuring stable flight paths and precise station-keeping. This stability is vital for tasks requiring fine control, such as manipulator operations, tool deployment, and close visual inspections. Furthermore, accurate motion compensation is crucial for acquiring high-quality data from onboard sensors like sonar and cameras during subsea surveys and mapping.