What is the role of motion monitoring in offshore operations?

Motion monitoring is a cornerstone of safety, operational efficiency, and asset protection in the offshore industry. Whether on vessels, platforms, or subsea equipment, precise, real-time measurement of movement across all six degrees of freedom (Roll, Pitch, Heave, Yaw, Surge, and Sway) is essential for effective decision-making in complex, dynamic marine environments.

Applications in Offshore Oil and Gas

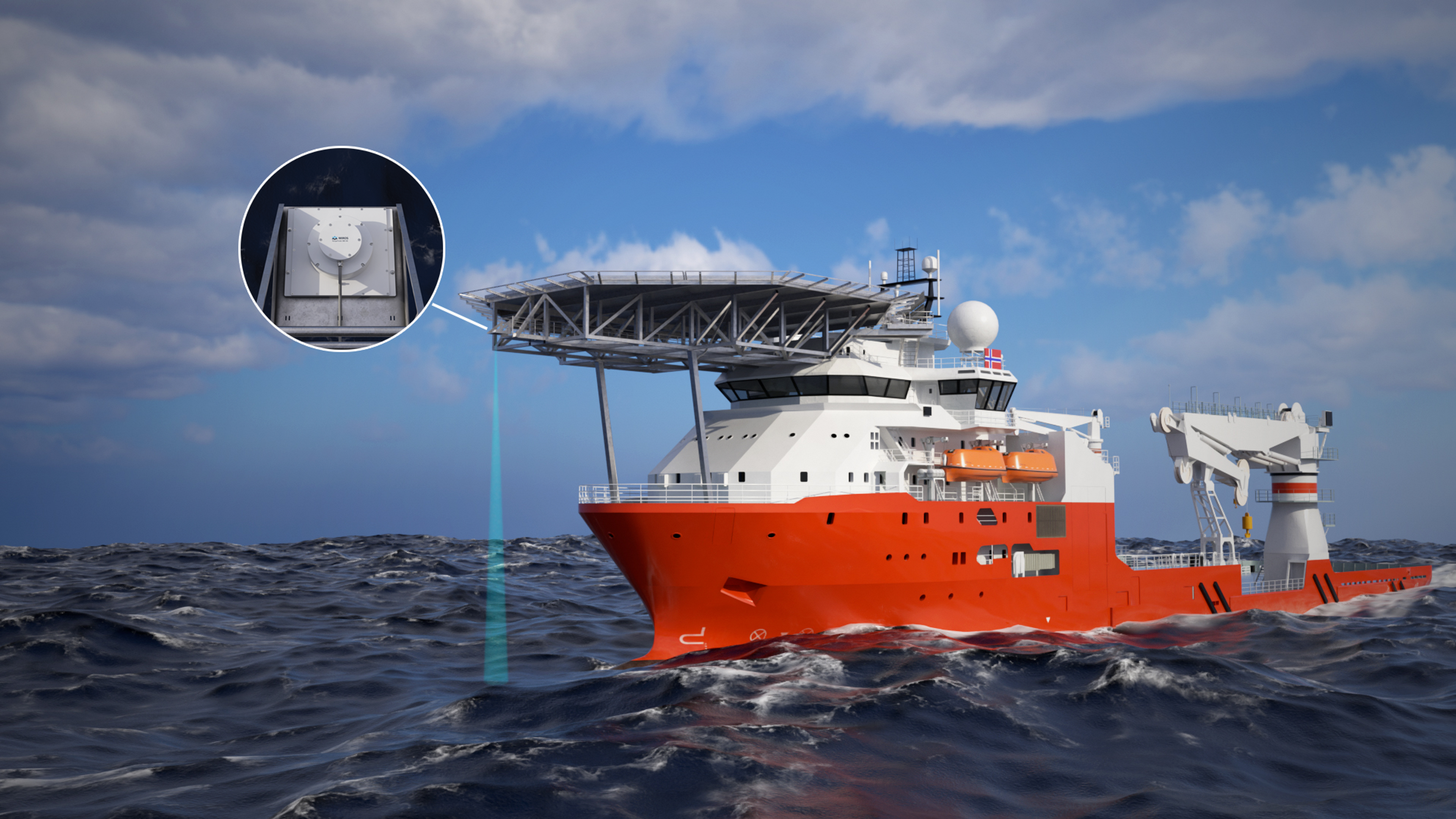

In offshore oil and gas, Norwegian Subsea’s Motion Reference Units (MRUs) deliver critical data for a range of essential systems:

- Dynamic Positioning (DP): MRUs provide motion-compensated GNSS antenna inputs and other reference data for precise station-keeping.

- Helideck Monitoring Systems (HMS): Accurate real-time Roll, Pitch, and Heave data ensure helicopter safety during landings and take-offs, in compliance with CAP 437 standards.

- Active Heave Compensation (AHC): MRUs stabilise winches, cranes, and launch and recovery systems (LARS), supporting safe lifting operations in high sea states.

- Motion Compensated Gangways: MRUs enable real-time motion correction for personnel transfer systems between vessels and offshore installations.

- Wave Radars: MRUs provide accurate real-time heave data to compensate downward-looking radar measurements for precise sea state assessment.

- Wind Lidar Buoys: MRUs correct for platform movement, ensuring stable wind data collection in offshore wind measurement campaigns.

Subsea Operations and Structural Monitoring

Motion monitoring also plays a vital role in subsea operations and structural health monitoring:

- ROV and AUV Navigation: MRUs provide 6DoF motion data for accurate navigation and control of Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs) during tasks like inspections, installations, and surveys.

- Subsea Surveys: Precise Roll, Pitch, and Heave compensation improves sonar data quality, reducing the need for repeated passes or extensive post-processing.

- Riser and BOP Monitoring: MRUs are used to assess motion and integrity of critical subsea infrastructure including risers and Blowout Preventers (BOPs).

- Structural Health Monitoring: MRUs track motion on both fixed and floating offshore structures, including platforms and offshore wind turbines.

Norwegian Subsea MRU Solutions

Norwegian Subsea offers a comprehensive range of high-performance MRUs tailored for offshore environments:

- MRU Marine: IP68-rated for topside or shallow water applications.

- MRU Subsea: Housed in a compact, robust titanium casing, depth-rated to 6000 metres, ideal for deepwater and subsea operations.

- MRU Ex: Certified for hazardous environments, including areas with explosion risks.

All our MRUs are engineered with advanced MEMS technology and proprietary sensor fusion algorithms. They support standard industry communication protocols such as UDP, Modbus TCP, and Ethernet/IP, ensuring seamless integration with control systems. With no need for recalibration in most cases, they offer long-term reliability and cost efficiency, making them suitable for both new installations and retrofit projects.