How is motion data filtered and analysed in real time by Motion Reference Units?

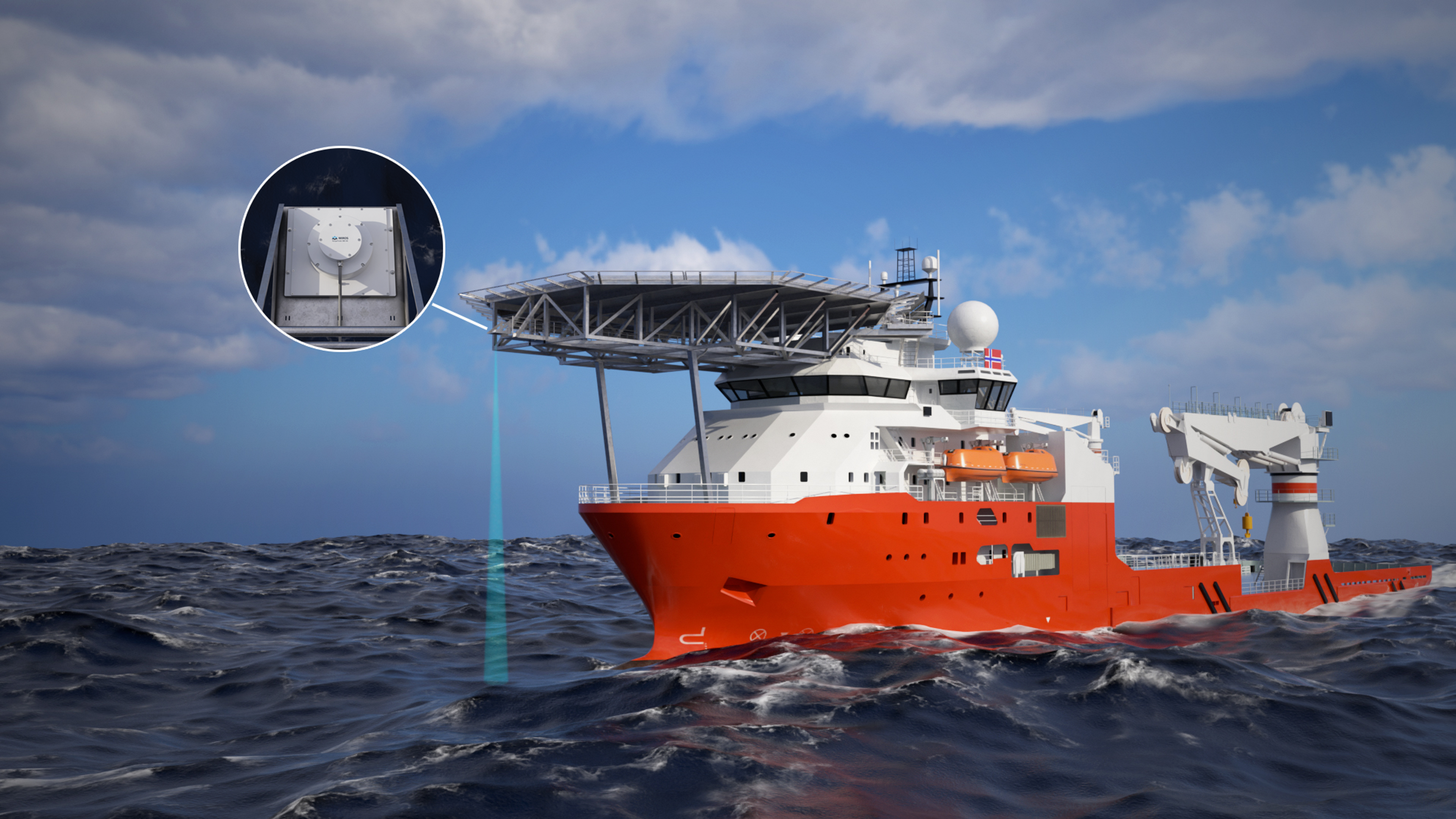

Accurate real-time motion data is essential for marine, offshore, and subsea operations. Norwegian Subsea’s Motion Reference Units (MRUs) are designed to deliver this through a combination of high-end MEMS sensors, advanced sensor fusion algorithms, and onboard data processing systems.

Data Filtering

MRUs apply advanced filtering techniques to raw sensor inputs to isolate true vessel motion and eliminate noise. Norwegian Subsea MRUs use a sophisticated Kalman Filter algorithm as part of their sensor fusion process, which intelligently processes input from MEMS accelerometers and gyroscopes. These filters are highly optimised to differentiate between actual vessel motion and unwanted disturbances such as vibration or sensor noise.

This filtering is essential in real-world maritime environments, where irregular waves and complex coupled motions can distort raw data. The effectiveness of our filtering techniques is validated in real sea conditions and directly affects the reliability of systems such as dynamic positioning (DP), sonar motion compensation, helideck monitoring systems (HMS), 3D motion compensated gangways, and active heave compensation (AHC).

Despite the complexity of internal filtering, users benefit from an intuitive interface. The filtered output is available via various standard protocols, and device configuration is managed easily through a browser-based setup interface.

Real-Time Data Analysis

The MRU’s onboard processing unit plays a vital role in real-time analysis. Sensor data is continuously processed internally with minimal latency, allowing the MRU to deliver high-accuracy motion measurements across all six degrees of freedom: Roll, Pitch, Yaw, Heave, Surge, and Sway.

This data is transmitted in real time to connected systems via Ethernet or serial connections (RS-232 or RS-485), supporting protocols such as UDP, Modbus TCP, Ethernet/IP, NMEA, or custom formats. While the MRU handles the real-time motion computation, further analysis or control decisions are typically carried out by the connected client system, relying on the high-fidelity, low-latency data stream from the MRU.

This combination of real-time onboard processing and precision filtering ensures that Norwegian Subsea MRUs provide stable, application-ready motion data critical for operational success in the harshest marine environments.