How is data filtering applied in Motion Reference Units?

Data filtering is a critical process within Motion Reference Units (MRUs) designed to refine raw sensor measurements by removing noise and isolating the true motion components. At Norwegian Subsea, our MRUs utilize advanced sensor fusion algorithms and Kalman Filter algorithm that intelligently process data from state-of-the-art MEMS accelerometers and gyroscopes.

These sophisticated algorithms act as highly optimized filters, effectively distinguishing between vessel motion and unwanted noise or vibrations. This ensures the delivery of exceptionally accurate and stable measurements for Roll, Pitch, Heave, Yaw, Surge, and Sway in real sea conditions with irregular waves and coupled motions.

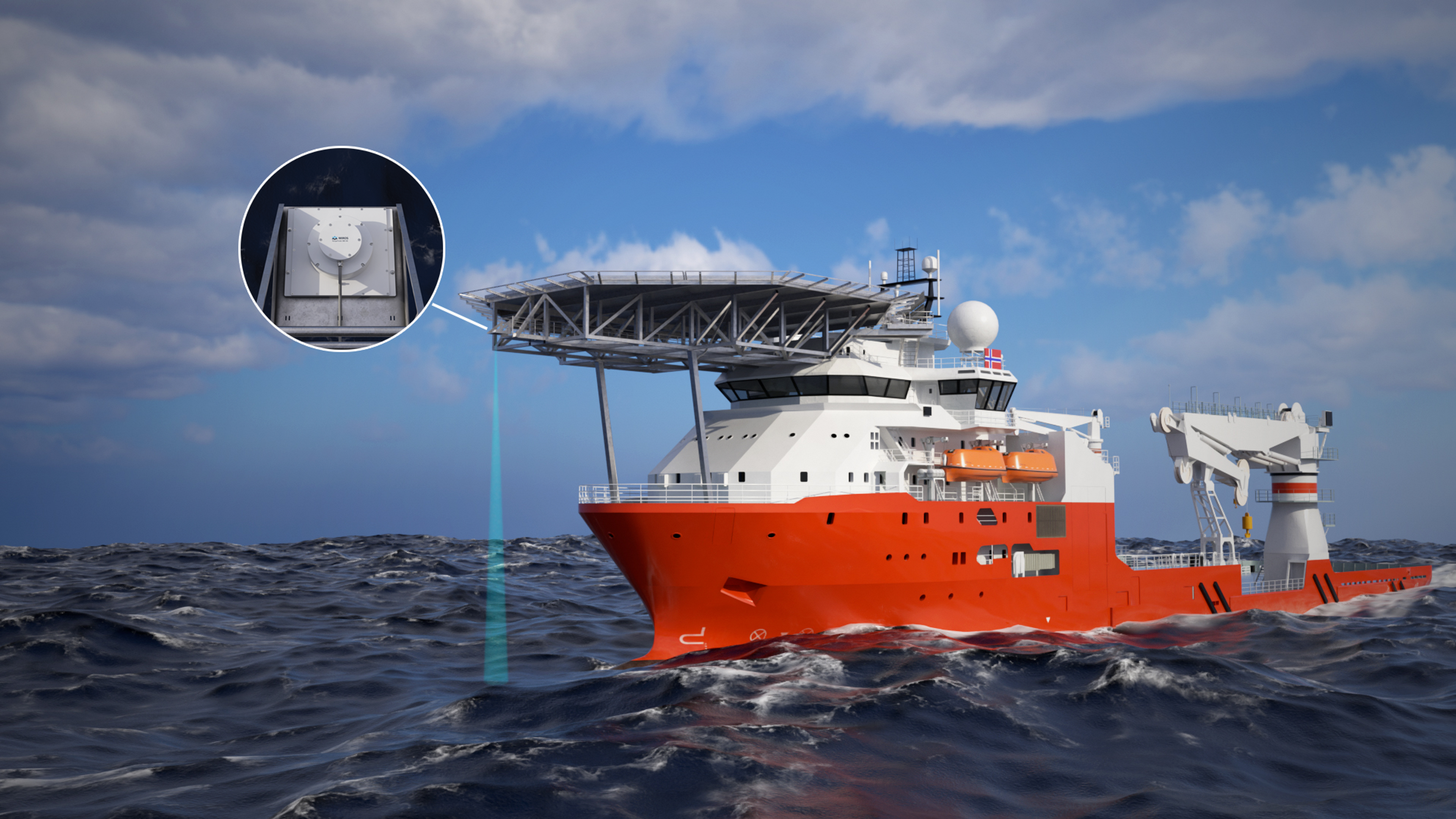

The quality of data filtering directly impacts the performance and reliability of systems relying on motion data. Our robust filtering techniques are validated in real sea conditions, providing the high-fidelity output required for demanding applications such as 3D motion compensated gangways, sonar motion compensation, Dynamic Positioning (DP), Active Heave Compensation (AHC), helideck monitoring (HMS) and much more.

While the internal filtering processes are complex, Norwegian Subsea MRUs are designed for ease of use. The filtered data is provided through various standard protocols, and users can access configuration settings via a user-friendly web interface, ensuring seamless integration and optimal performance with minimal setup.