How is motion monitoring used in offshore oil and gas?

Motion monitoring is fundamental to ensuring safety, operational efficiency, and asset integrity within the offshore oil and gas industry. Accurate, real-time measurement of vessel and equipment motion, including Roll, Pitch, Heave, Yaw, Surge, and Sway (6 Degrees of Freedom - 6DoF), is essential for conducting complex operations safely and effectively in dynamic maritime environments.

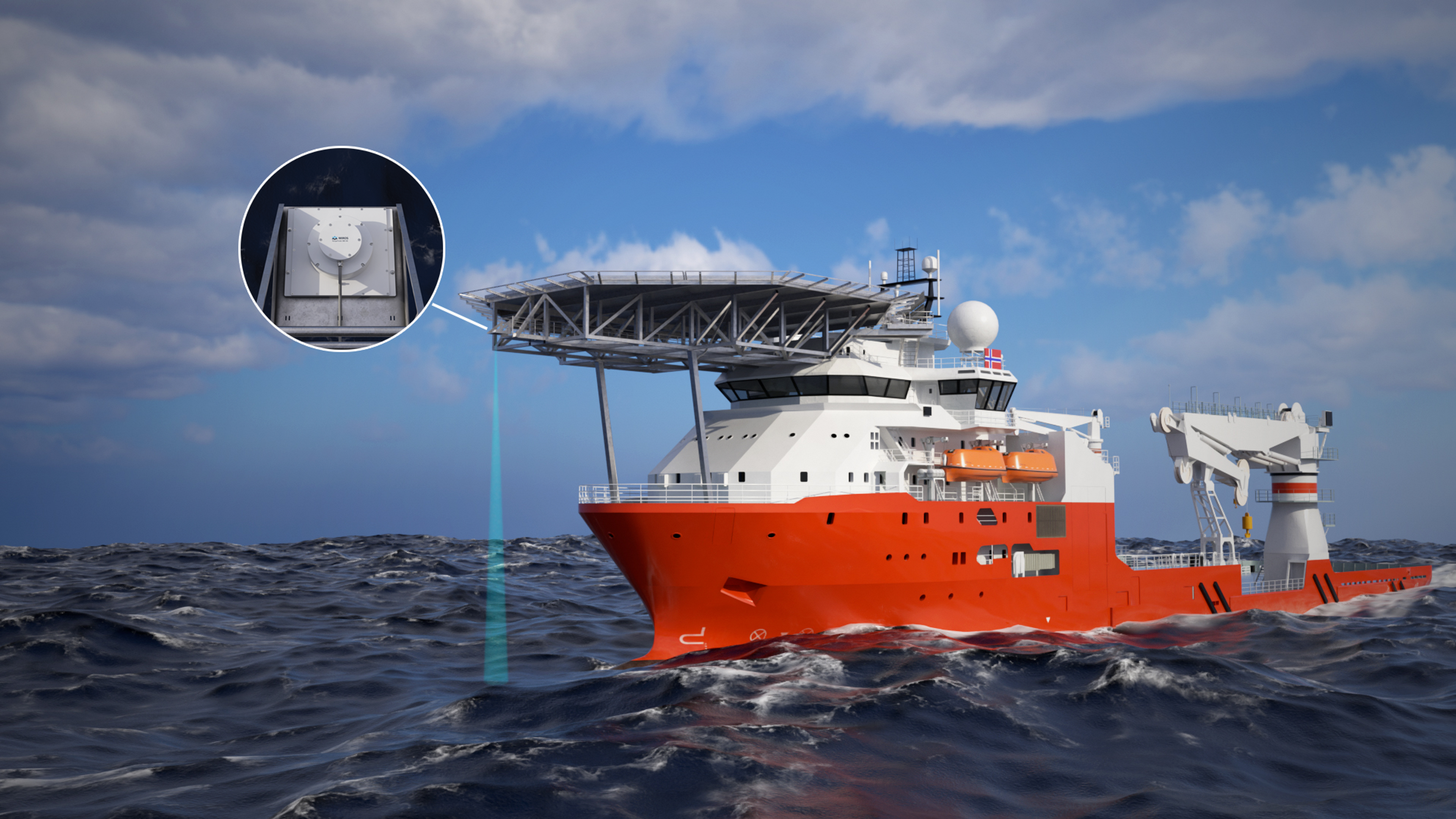

Norwegian Subsea's high-performance Motion Reference Units (MRUs) provide the critical motion data required by various essential systems. This includes Dynamic Positioning (DP) systems for precise vessel station-keeping, Helideck Monitoring Systems (HMS) to ensure safe helicopter operations, Active Heave Compensation (AHC) systems for stable crane and winch performance, and Motion Compensated Gangways that allow for secure personnel transfers between vessels and installations.

Our robust sensors are also integral to a wide range of subsea activities. They enable precise navigation and control for Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs), facilitate accurate subsea surveys, and provide vital monitoring for critical equipment such as Blowout Preventers (BOPs) and risers. Furthermore, our MRUs can be employed for structural health monitoring of fixed and floating offshore platforms.

Norwegian Subsea provides a comprehensive range of reliable MRUs specifically engineered for the demanding conditions encountered offshore. This includes the versatile, IP68-rated MRU Marine for deck or shallow water use, the 6000m depth-rated titanium MRU Subsea for deepwater applications, and the certified MRU Ex for deployment in hazardous areas. Our sensors are known for their high accuracy, robust design, ease of integration using standard industry protocols, and cost-effectiveness, making them ideal for both new projects and as drop-in replacements for retrofitting older systems.