What sensor technologies are used in ROVs?

Remotely Operated Vehicles (ROVs) rely on a suite of sophisticated sensors to navigate complex subsea environments, perform intricate tasks, and gather data. Key sensor technologies typically include imaging sonar for obstacle avoidance and mapping, cameras for visual inspection, Doppler Velocity Logs (DVLs) for measuring speed over the seabed, depth sensors, altimeters, and crucially, high-performance motion sensors.

Motion Reference Units (MRUs) are fundamental components within an ROV's sensor package. They provide precise measurements of the vehicle's orientation and motion across all six degrees of freedom (6DoF): Roll, Pitch, Heave, Yaw, Surge, and Sway. This high-fidelity motion data is essential for vehicle stability, accurate navigation when integrated with systems like DVLs or acoustic positioning (USBL/LBL), and precise control of manipulators and tooling.

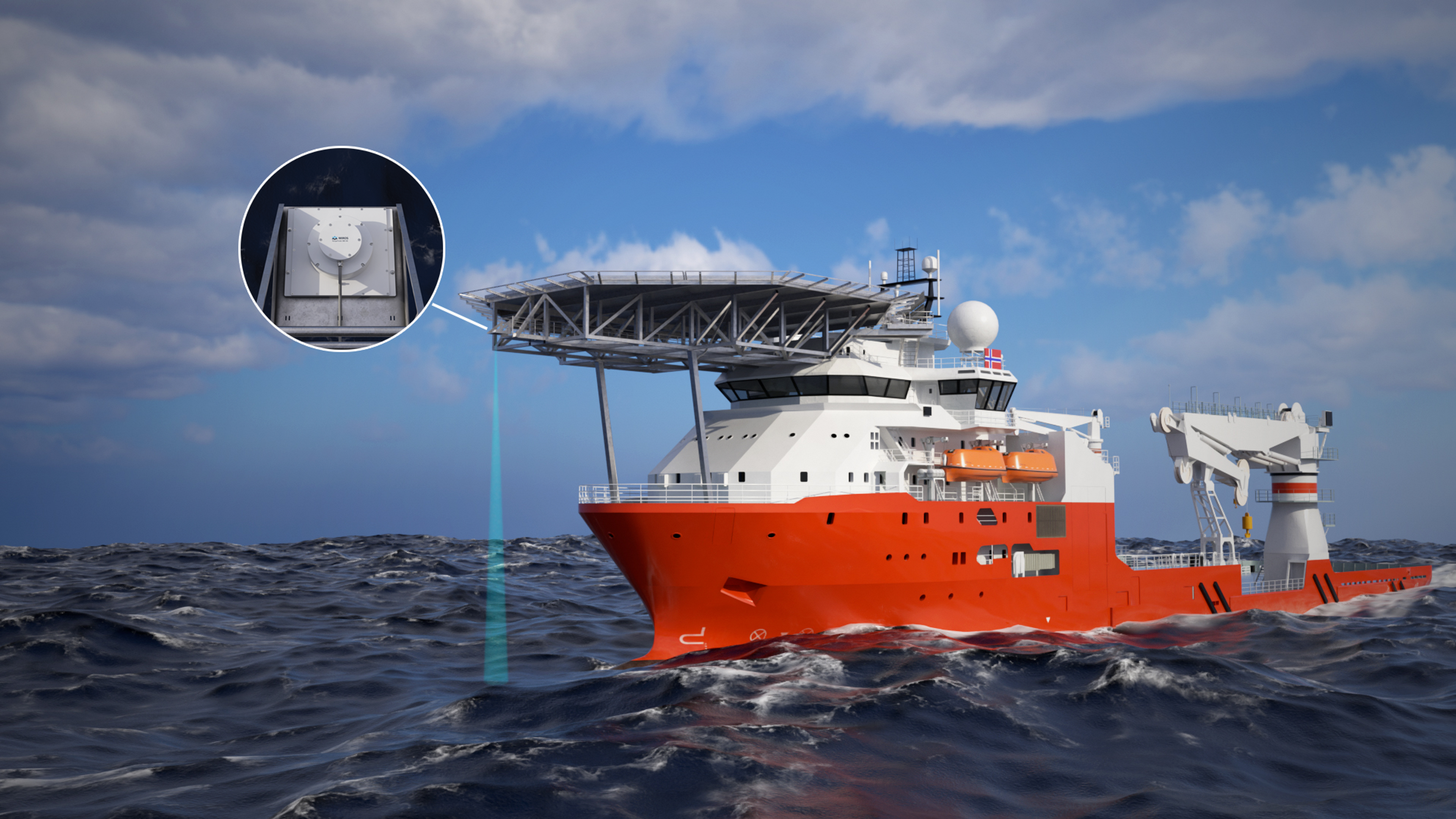

Norwegian Subsea specializes in developing advanced MRUs utilizing state-of-the-art MEMS sensor technology and robust sensor fusion algorithms, delivering the high accuracy and reliability required for demanding ROV operations. Our MRU Subsea is specifically designed for these applications, featuring a compact, 6000-meter depth-rated titanium housing, a standard Subconn connector for easy integration, and flexible Ethernet and serial communication options supporting various industry protocols. For applications primarily requiring orientation data, cost-effective Inclinometer/VRU versions are also available, offering the same high Roll and Pitch accuracy.