How do I choose the right Motion Reference Unit for subsea applications?

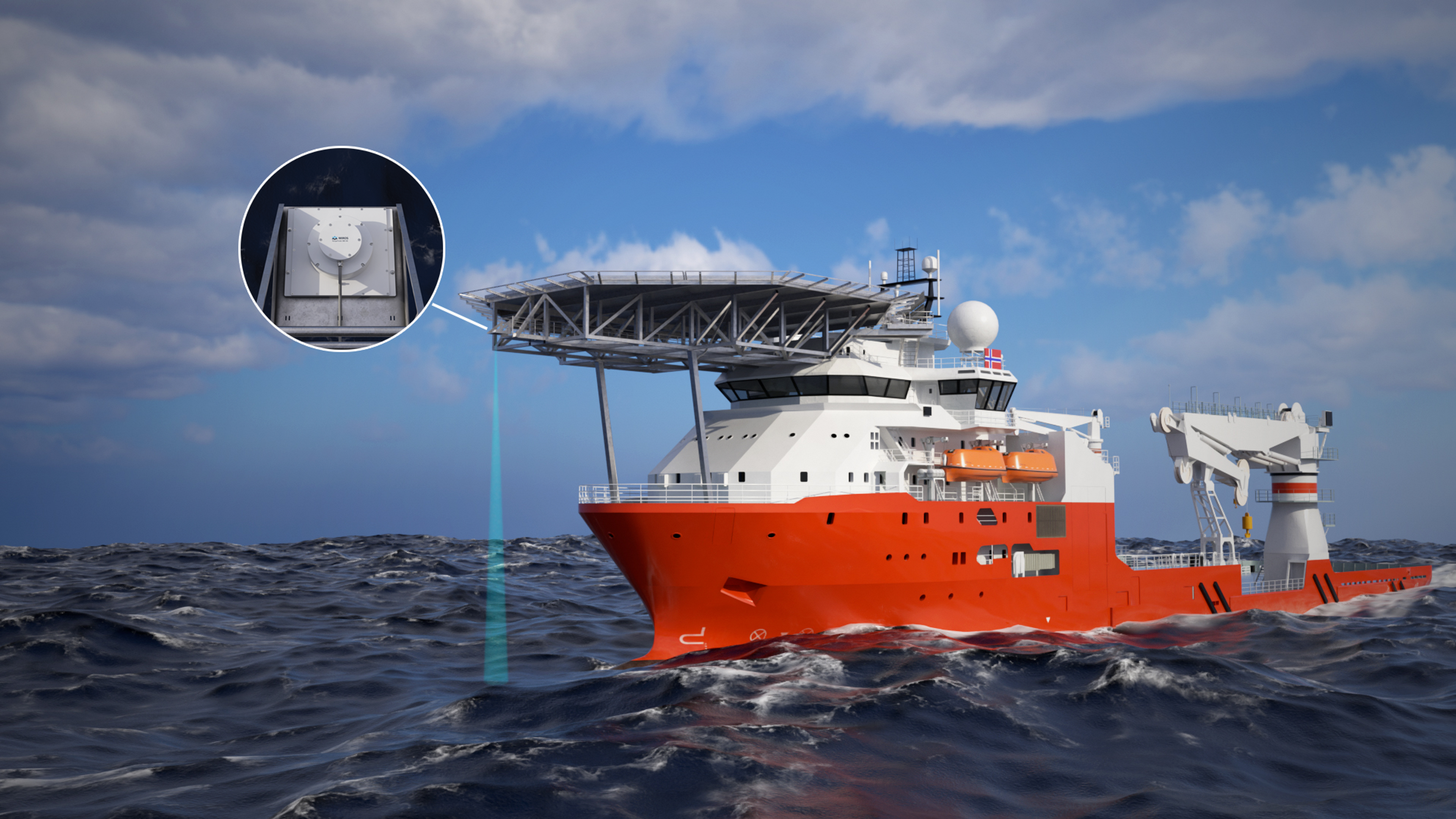

When selecting a motion sensor for subsea applications, the right choice combines robust design, deep‑water capability, high accuracy, and ease of integration. At Norwegian Subsea we recommend our MRU Subsea model for these demanding conditions.

Why choose the MRU Subsea?

The MRU Subsea is engineered specifically for underwater operations. It features a compact titanium housing rated to 6000 metres depth, making it ideal for use on ROVs, AUVs, riser monitoring systems, BOP monitoring, subsea surveys and inspection platforms. Its small footprint and ability to be mounted in any orientation allow for flexible installation in space‑constrained subsea environments.

It offers high‑accuracy 6 Degrees of Freedom (6DoF) motion data including Roll, Pitch, Yaw, Heave, Surge and Sway. Roll & Pitch accuracies are available in ±0.05°, ±0.02° and ±0.01° options depending on the series. The unit integrates seamlessly via a Subconn wet‑mateable connector and supports both Ethernet (UDP, Modbus TCP, Ethernet/IP) and serial (RS‑232 or RS‑485) communication. It is built with advanced MEMS sensors and proprietary fusion algorithms, delivering validated real‑sea performance often without the need for recalibration.

For projects that only require Roll and Pitch measurements, Norwegian Subsea also offers VRU/Inclinometer versions of the MRU model, offering the same high angular accuracy at lower cost.

How to buy the MRU Subsea

To purchase a motion sensor for subsea use, please contact Norwegian Subsea directly. Our team will guide you through selecting the appropriate model based on your environmental conditions, accuracy requirements, data protocol needs and connector options. Provide us with your application details and we will support you with a tailored solution.