How can I improve the accuracy of subsea sensors?

Improving the accuracy of subsea sensors fundamentally relies on selecting a high-performance unit designed specifically for the demanding underwater environment. At Norwegian Subsea, we achieve superior accuracy through a combination of state-of-the-art MEMS sensor technology, advanced sensor fusion algorithms, and robust hardware engineering, validated in real sea conditions.

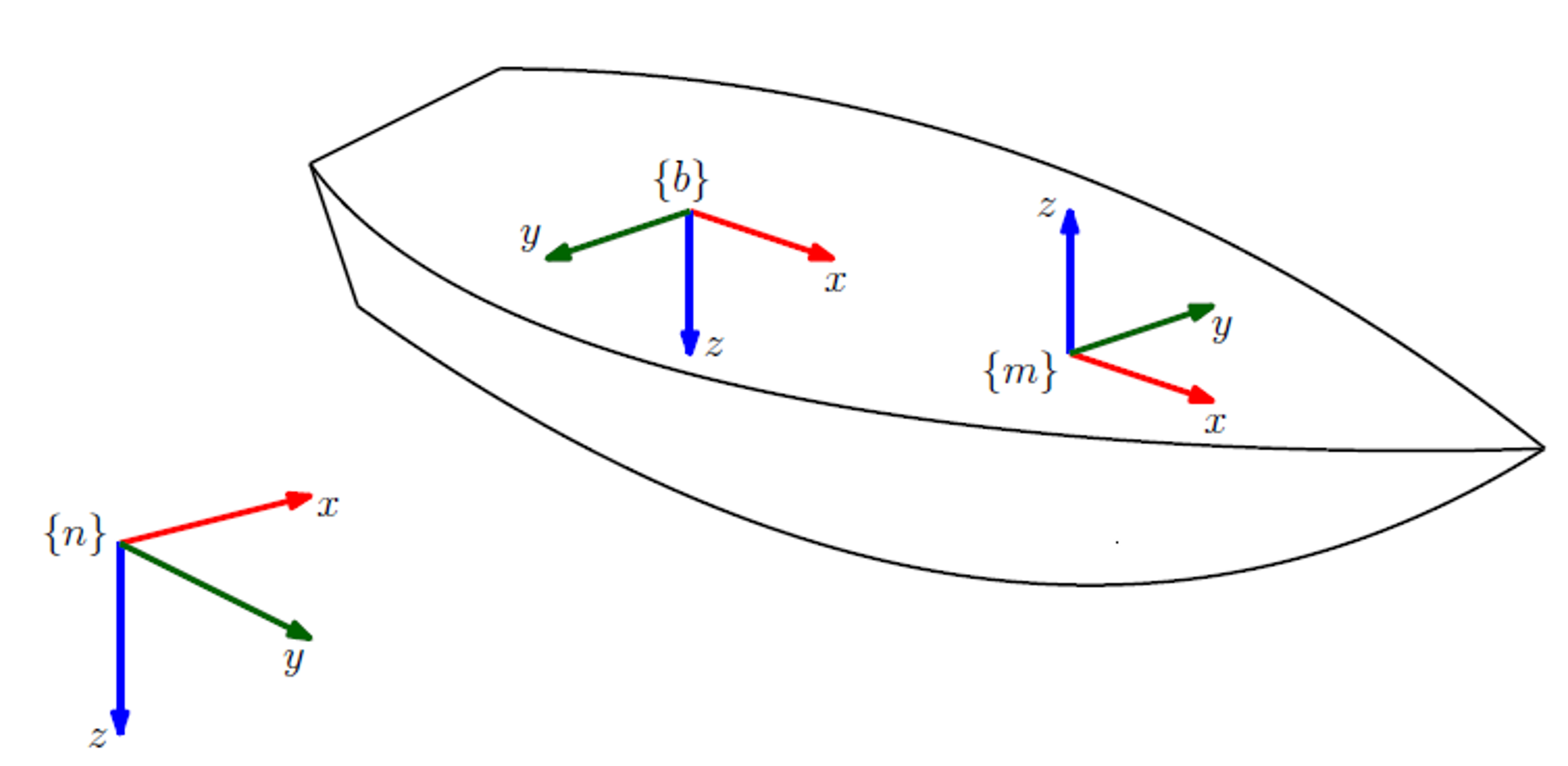

Our algorithms are crucial for filtering noise and accurately calculating motion parameters like Roll, Pitch, Heave, Surge, Sway, and Yaw (6DoF), even under complex, irregular motion patterns typical of subsea operations. Furthermore, our sensors undergo rigorous testing and validation in real sea conditions, ensuring their performance specifications are met in the environments where they will be deployed.

The Norwegian Subsea MRU Subsea exemplifies this approach. Housed in a compact, 6000m depth-rated titanium casing, it offers exceptional durability. It is available in different accuracy tiers (±0.05°, ±0.02°, ±0.01° Roll/Pitch accuracy) to meet specific project requirements. We also offer an Inclinometer/VRU version for applications requiring only high-accuracy Roll and Pitch data.

Accuracy is maintained over the long term, as our MRUs are factory calibrated and typically do not require recalibration during their operational life for most applications. Easy integration via standard protocols (Ethernet, RS-232/RS-485, Modbus TCP) and Subconn connectors ensures that the high-quality data can be reliably transmitted to your systems. Choosing a sensor engineered for performance and reliability, like those from Norwegian Subsea, is the most effective way to ensure high accuracy for your subsea applications.