What is an Inertial Measurement Unit and how does it work?

An Inertial Measurement Unit (IMU) is an electronic device that uses accelerometers and gyroscopes, and sometimes magnetometers, to measure and report an object's linear acceleration and angular velocity along three orthogonal axes (X, Y and Z). It provides raw data outputs without performing any internal processing. As such, IMUs do not calculate attitude (roll and pitch), velocity or position on their own. Any application requiring this type of information must perform additional data processing externally.

Applications of IMUs

IMUs are ideal for use in systems where raw motion data will be processed by external software or hardware. Typical examples include basic navigation systems, robotics control, and camera or drone stabilisation. They are most suitable where cost, simplicity, and flexibility for custom processing are key considerations.

What Sets MRUs Apart

In contrast, a Motion Reference Unit (MRU) is a more advanced, self-contained device. It combines MEMS-based accelerometers and gyroscopes—similar to an IMU—with advanced sensor fusion algorithms. This onboard processing enables the MRU to output accurate, real-time orientation (Roll, Pitch, Yaw) and motion data (Heave, Surge and Sway) in all six degrees of freedom (6DoF).

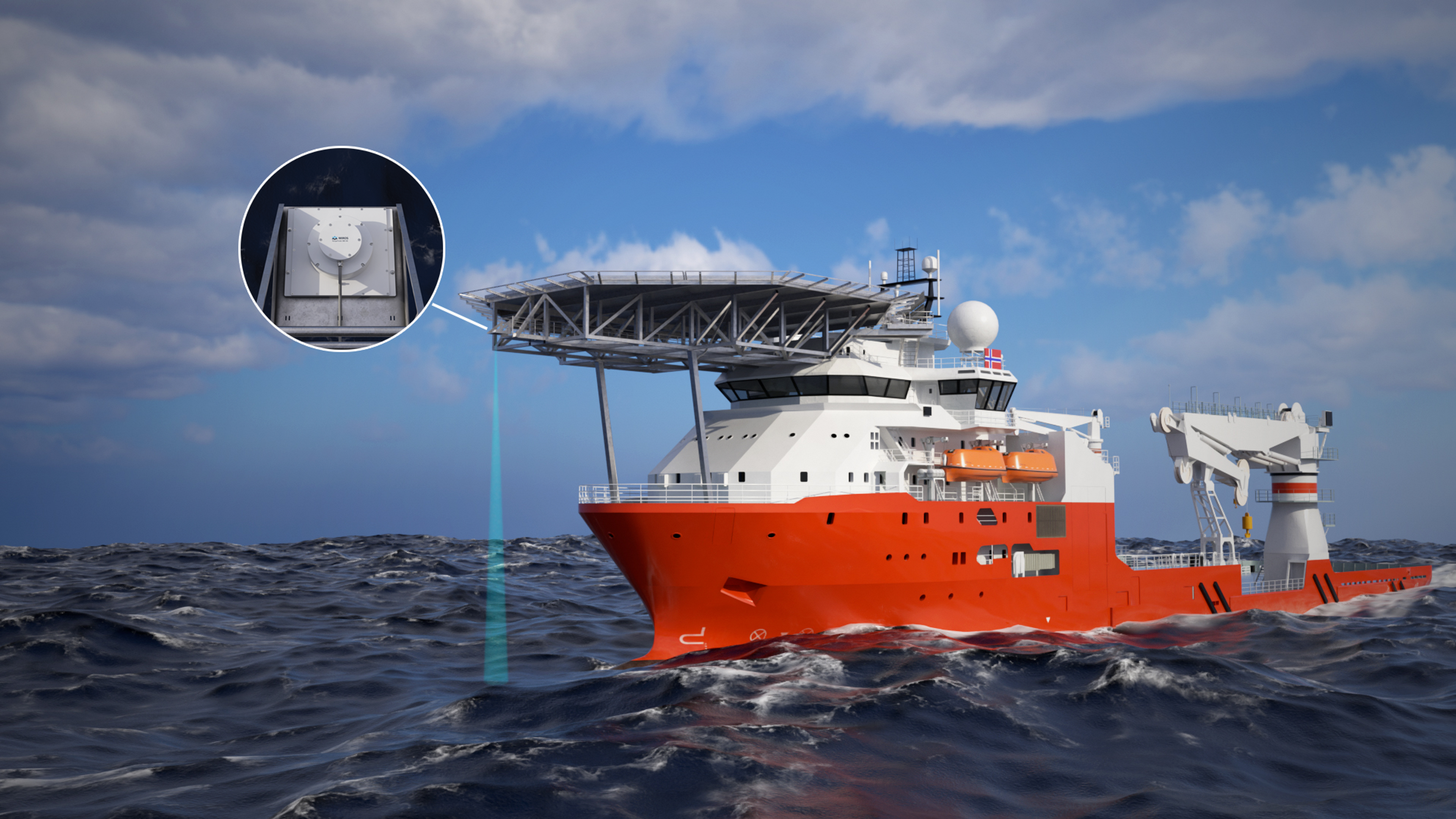

Norwegian Subsea MRUs are designed and tested for performance in marine, offshore and subsea environments. They provide precise, application-ready motion data, essential for dynamic positioning, hydrographic surveying, heave compensation and related tasks. The high accuracy of these sensors (with options down to ±0.01° Roll and Pitch) is maintained over time, and recalibration is generally unnecessary.

Key Differences Between IMUs and MRUs

While both IMUs and MRUs measure motion using accelerometers and gyroscopes, the key difference lies in how the data is processed and used. IMUs supply raw data only, without any internal algorithms or computation. They are best suited for systems where external software handles the data interpretation and conversion into usable outputs such as attitude or position.

MRUs, on the other hand, process the sensor data internally using advanced fusion algorithms. They output real-time, high-accuracy measurements across all six degrees of freedom. This makes MRUs highly effective in environments with complex and irregular motion, such as marine or offshore applications, where reliable and immediate data is essential. Additionally, MRUs typically require less ongoing calibration and can be integrated directly into control and monitoring systems without further processing.

Selecting the Right Device

- Use an IMU when raw data and external processing flexibility are required.

- Use an MRU when accurate, real-time motion data is needed, especially in dynamic marine environments.