Miros-Group reduces wave radar maintenance and lifetime costs using Norwegian Subsea Motion Reference Units

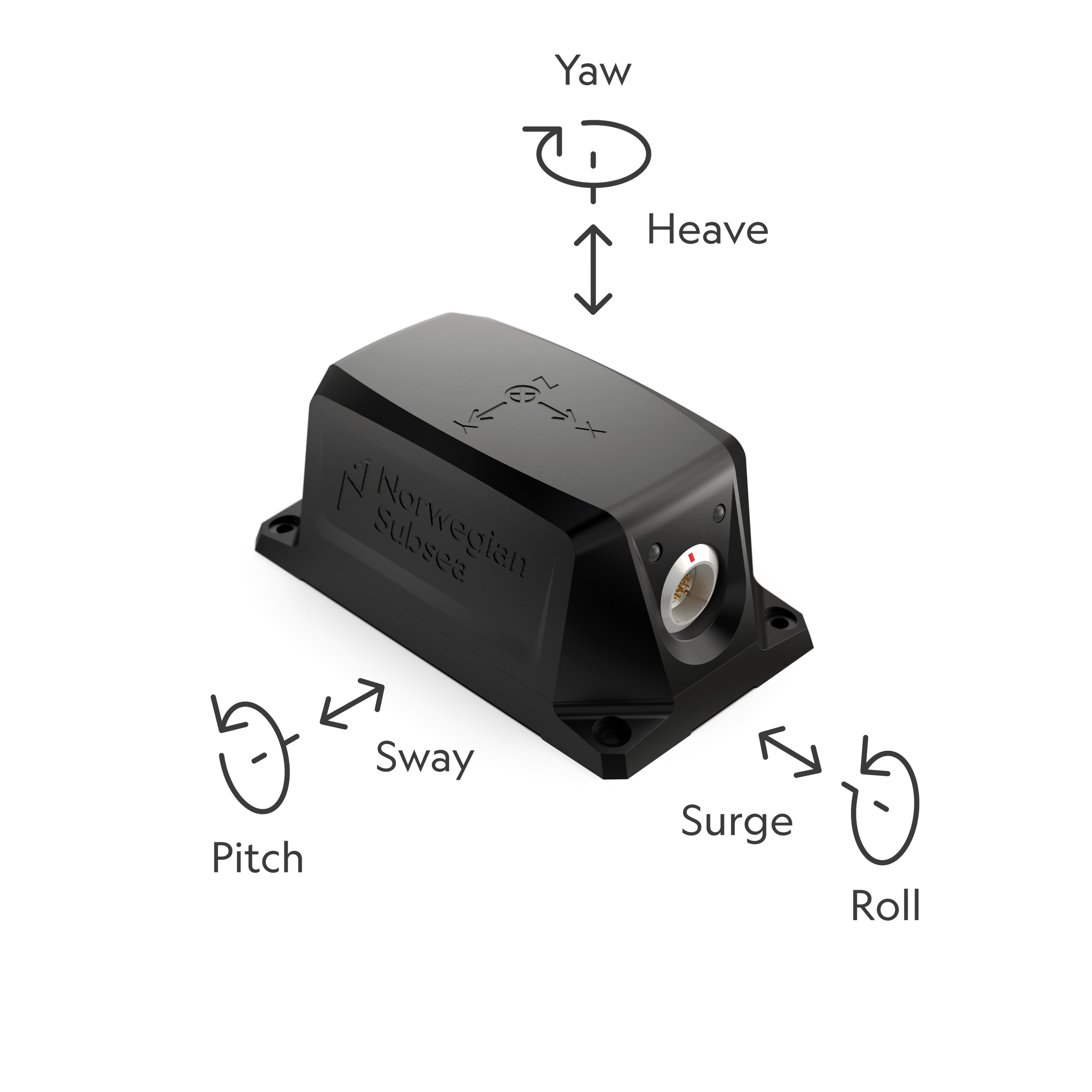

Motion Reference Units (MRUs) are crucial in wave radar technology, providing precise measurements of platform motion to accurately separate true wave patterns from a vessel's movements, therefore ensuring reliable data for maritime operations.

However, before leading wave radar manufacturer Miros started working with Norwegian Subsea in 2016, it could be said that the MRU market was holding their potential back.

About the project

- Wave radar tech leader integrates compact, calibration-free MRUs

- No MRU recalibration means reduced lifetime costs and downtime

- Deep integration simplifies installations and reduces failure risks

- Comparable data quality to established solutions but at half the cost

- Miros leverages MRU data for AI-powered wave motion prediction

The challenge: Bulky, Expensive, and High-Maintenance MRUs

The MRUs used for precision wave radar motion compensation have traditionally been bulky and expensive, in addition to needing costly and time-consuming calibration at the manufacturers premises every few years.

The de facto industry standard MRU has also been subject to strict import and export processes, so end-users in countries like Brazil might wait six months to get their wave radar up and running when recalibration was needed. The overall cost of recalibration could be as much, if not more than the original system even.

Innovation in demand: The search for a better solution

According to Jonas Røstad, Chief Commercial Officer, Miros, these legacy MRUs increased system complexity as well. “They were too big to go directly inside our products. So, we had the wave radar with cables connecting to an external MRU as well as a separate computer for calculations. It was convoluted, with multiple points of potential failure – especially the cables.”

Looking to innovate its products for a new generation, Miros needed something new: an MRU that was smaller and more affordable. And calibration and maintenance-free.

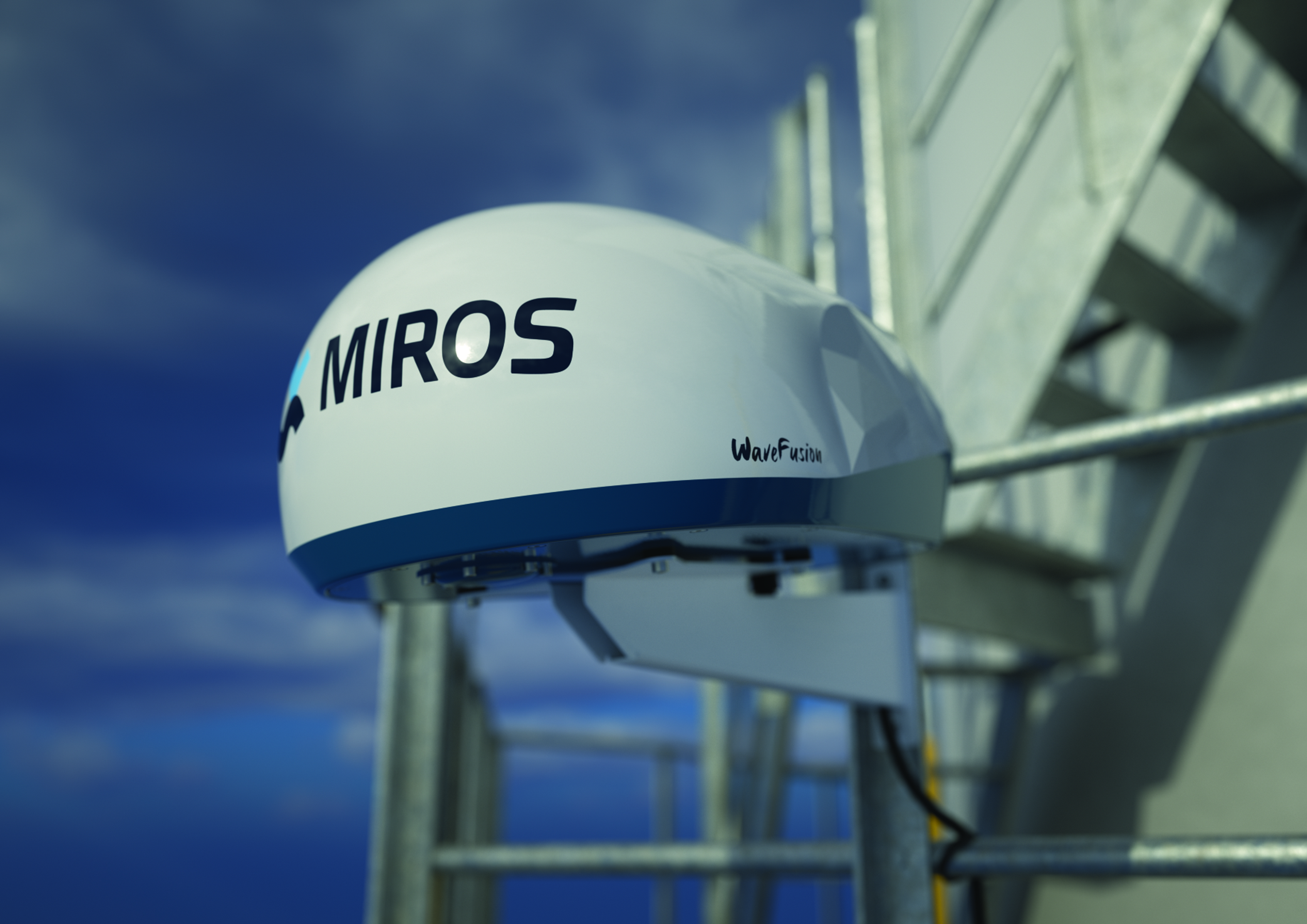

The solution: MRU directly integrated inside the Miros’ wave radar

They are rock solid. Many Norwegian Subsea MRUs have been running 24/7 inside Miros products for up to eight years without issue, producing real-time data every second.

Chief Commercial Officer, Miros

Norwegian Subsea was able to deliver just that in the form of an OEM MRU which integrated directly into Miros’ wave radar systems, eliminating the need for any external cabling and additional hardware. “The control and time synchronisation became so much easier. The hassle and cost of cables – it was all taken away,” Jonas explains.

A gamechanger: No more recalibration

Crucially, the lack of a need for recalibration in Norwegian Subsea MRUs has been a gamechanger. Traditional MRUs require recalibration every 2-4 years, leading to operational downtime, logistical complications, and added expenses, in addition to potential human error.

“We had a system with an MRU from another supplier that needed recalibration,” Jonas said. “Since the MRU had to be sent away, the system was out of action for a while, but this was planned for. When the MRU was returned however, it was mounted upside down, so it was impossible to get accurate wave height data. Now we just have the MRU inside the wave radar unit, and it never needs to come out.”

Reliability and Longevity: "Rock Solid" Performance

Reliability has also been a defining feature of Norwegian Subsea MRUs according to Jonas. “They are rock solid,” he says, noting that many Norwegian Subsea MRUs have been running 24/7 inside Miros products for up to eight years without issue, producing real-time data every second. Such longevity reduces lifetime costs and ensures uninterrupted operations for Miros' clients.

Transforming Miros’ Wave Radar Systems

The integration of Norwegian Subsea MRUs has enhanced Miros' products, delivering benefits for both the company and its customers. The products strike a perfect balance between affordability and performance, meeting all operational requirements at a price point that could not have been dreamed of only five years ago.

And although Miros does not need to use Norwegian Subsea’s flagship models to ensure the quality of data across its wave radar systems, the MRUs consistently deliver the accuracy and reliability needed for real-world applications.

The impact: Safer and More Efficient Offshore Operations

The motion compensation industry was overmature with too few players. Norwegian Subsea disrupted that business, bringing the sector several steps ahead.

Chief Commercial Officer, Miros

The impact: Safer and More Efficient Offshore Operations

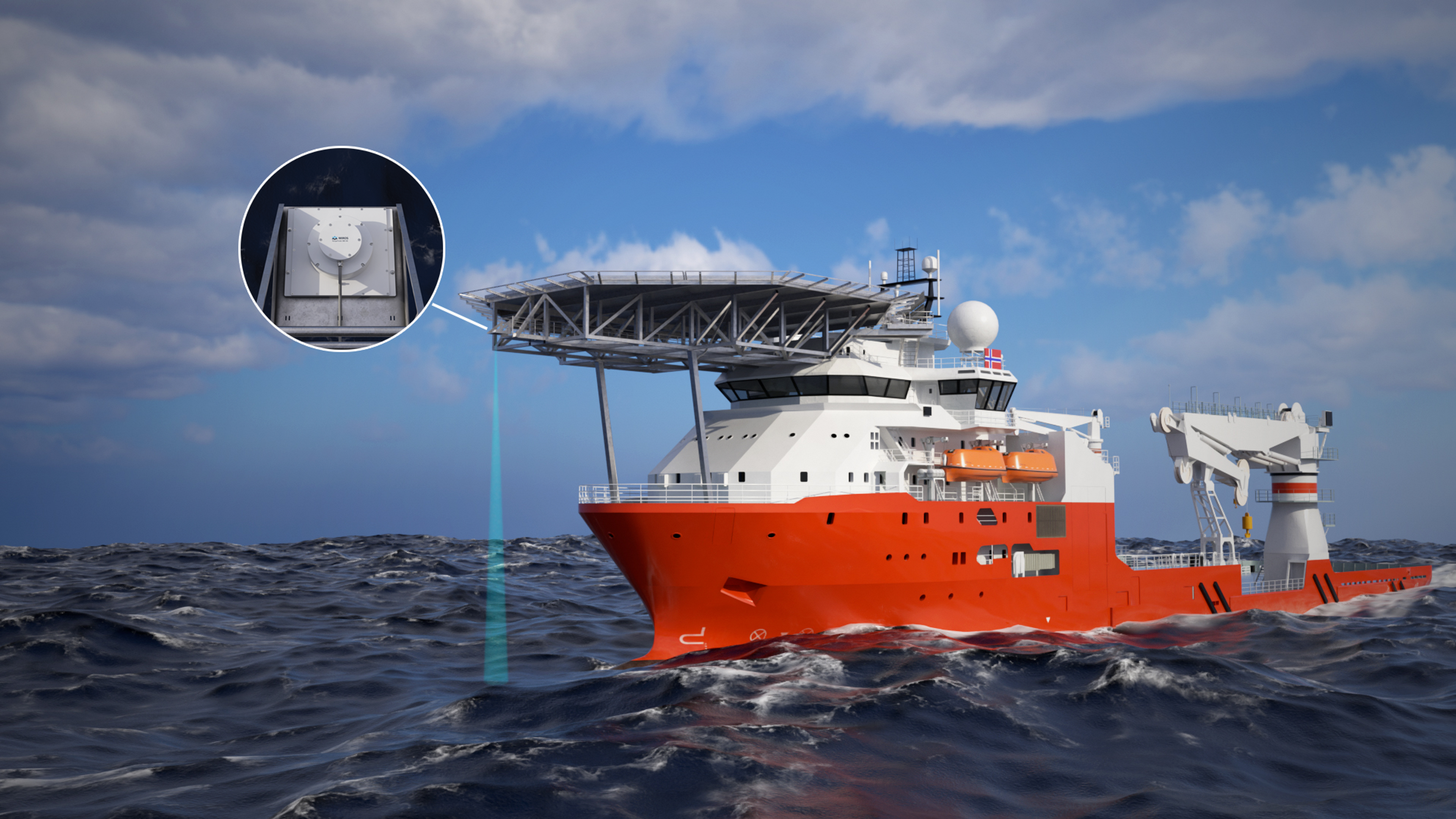

For Miros’ customers, the use of Norwegian Subsea MRUs translates into safer, more efficient operations. Many offshore applications rely on precise wave data to make critical decisions, such as when to transfer goods or personnel between vessel and platform.

Traditionally, such decisions depended on subjective assessments – “the captain’s calibrated eyeball” according to Jonas. Now users can enjoy wider operational windows based on dependable and verifiable data from the MRU and wave radar.

Cloud-Based Decision Support

The objectivity of wave radar is vital, especially as Miros is able to provide the data its systems collect in the cloud. It takes the pressure to make on the fly decision away from captains as teams on shore can make decisions based on real-time data – including from the MRUs, to ensure safety and operational excellence at sea.

Pushing the Boundaries: AI-Powered Wave Prediction

The leading wave radar manufacturer is also applying Norwegian Subsea MRU data to ensure the accuracy of its next game changing innovation, the prediction of waves and vessel motion through the pairing of radar technology and Artificial Intelligence.

Called PredictifAI, the system provides a real-time, in-operation prediction of the wave field that vessels will encounter and the associated wave-induced vessel motion up to a couple of minutes in advance. “Together with our radars and the new AI, Norwegian Subsea MRU data is a really important part of the system,” explains Jonas.

Disrupting an Overmature Industry

While Miros has driven the innovation behind PredictifAI, their collaboration with Norwegian Subsea reflects how innovation can disrupt legacy industries. “The motion compensation industry was overmature with too few players,” Jonas remarks. “Norwegian Subsea disrupted that business, bringing the sector several steps ahead.”

About the client

Miros

Miros delivers AI-powered ocean insights with IoT-enabled sensors and intelligent analytics, empowering safer offshore operations, wave and vessel motion prediction, and environmental monitoring, backed by 40+ years of expertise and trusted by global industry leaders. The company began as a research project with Equinor and the Norwegian Research Council, aiming to replace traditional wave buoys with a solution that would be less costly, easier to maintain and safer for ships. The result was a radar system for installation on ships and other floating platforms. It provided better wave state data, but at a fraction of the cost and without being a potential safety hazard. It was the forerunner to Miros' current flagship products in the sector, the Wave & Current Radar (SM-050) and the RangeFinder (SM-140), which are used on floating platforms and vessels respectively. These systems are the state-of-the-art in wave measurement technology, but both need motion compensation to provide accurate and actionable data. Which is where Norwegian Subsea's Motion Reference Units (MRUs) come in.