Making Structural Health Monitoring smarter with Motion Reference Units

As the maritime industry accelerates its journey towards smarter, more efficient digital operations, structural health monitoring systems are playing a central role in operational efficiency, safety and sustainability.

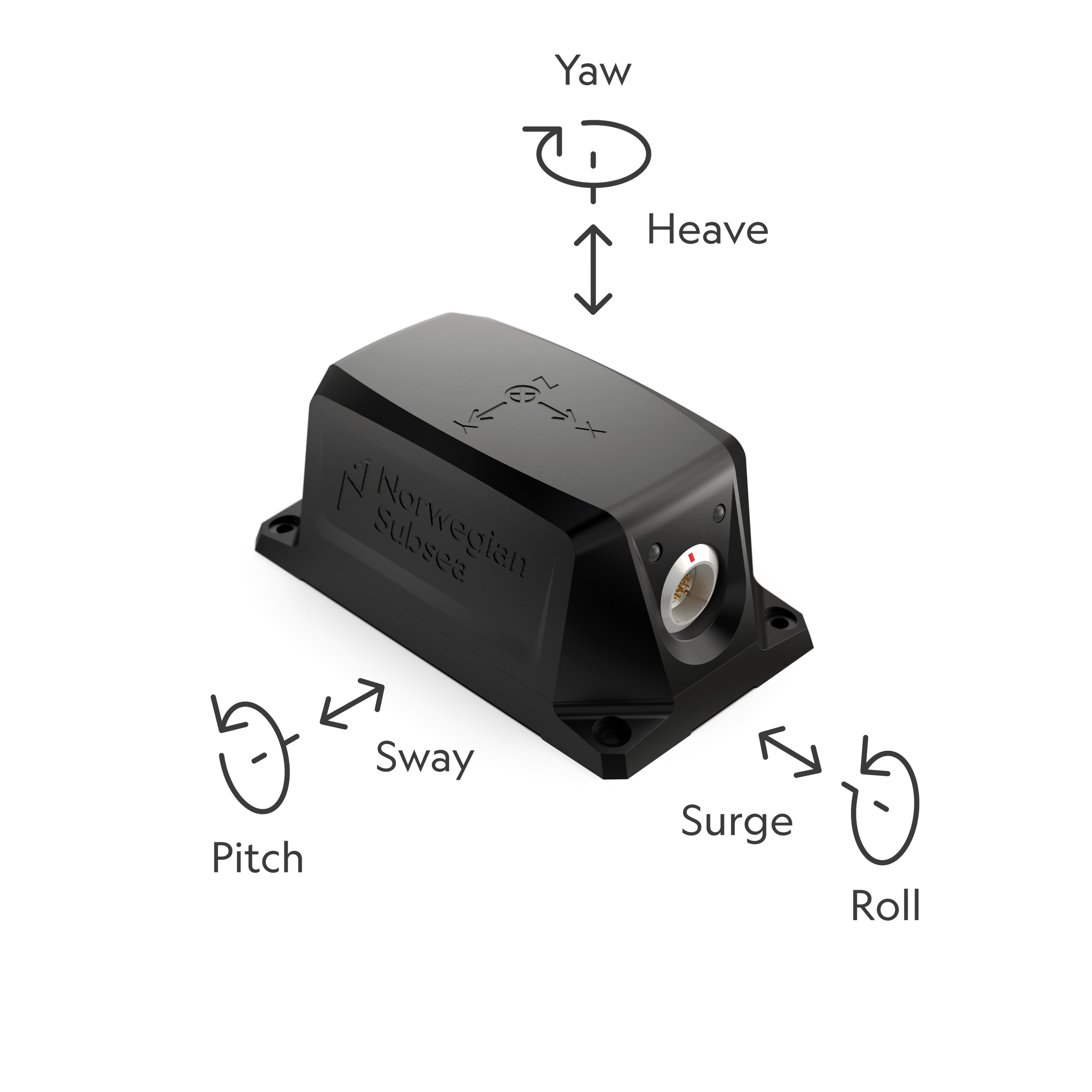

These systems increasingly depend on real-time, high-fidelity data from Motion Reference Units (MRUs) to contextualise structural stresses with the vessel’s motion in a given sea state. This is especially important in meeting the evolving requirements of classification society SMART notations from bodies such as the American Bureau of Shipping (ABS) and DNV.

About the collaboration

- MRUs help link hull stress data with ship motion and sea state conditions

- Light Structures chooses Norwegian Subsea MRUs to support SMART notations

- Motion data enables earlier anomaly detection and improved maintenance decisions

- Class society approvals drive increased adoption of hull monitoring and MRU systems

- MRUs help boost digitalisation, fuel efficiency, and vessel lifecycle management

The Challenge: Integrating motion data with precision structural measurements

"Accurate motion data from MRUs is a prerequisite… especially when paired with advanced hull stress and fatigue monitoring technologies."

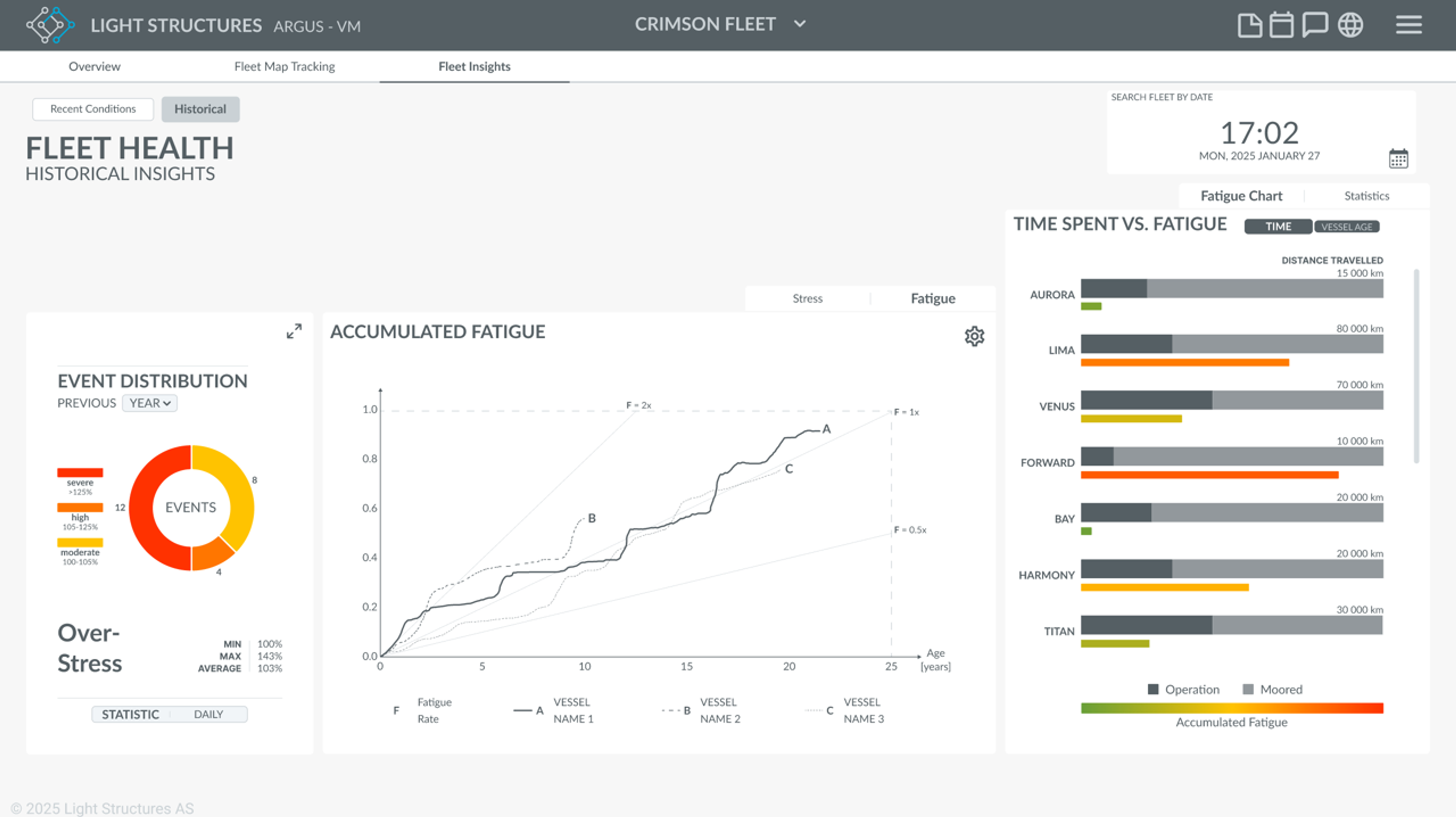

Structural integrity has become a continuous digital process. With the advent of SMART class notations, vessel owners and operators can significantly optimise vessel and fleet operations with verifiable, real-time structural data that can support predictive maintenance, performance optimisation and compliance with environmental goals. Accurate motion data from MRUs is a prerequisite to achieving these objectives, especially when paired with advanced hull stress and fatigue monitoring technologies.

Pioneering structural health monitoring

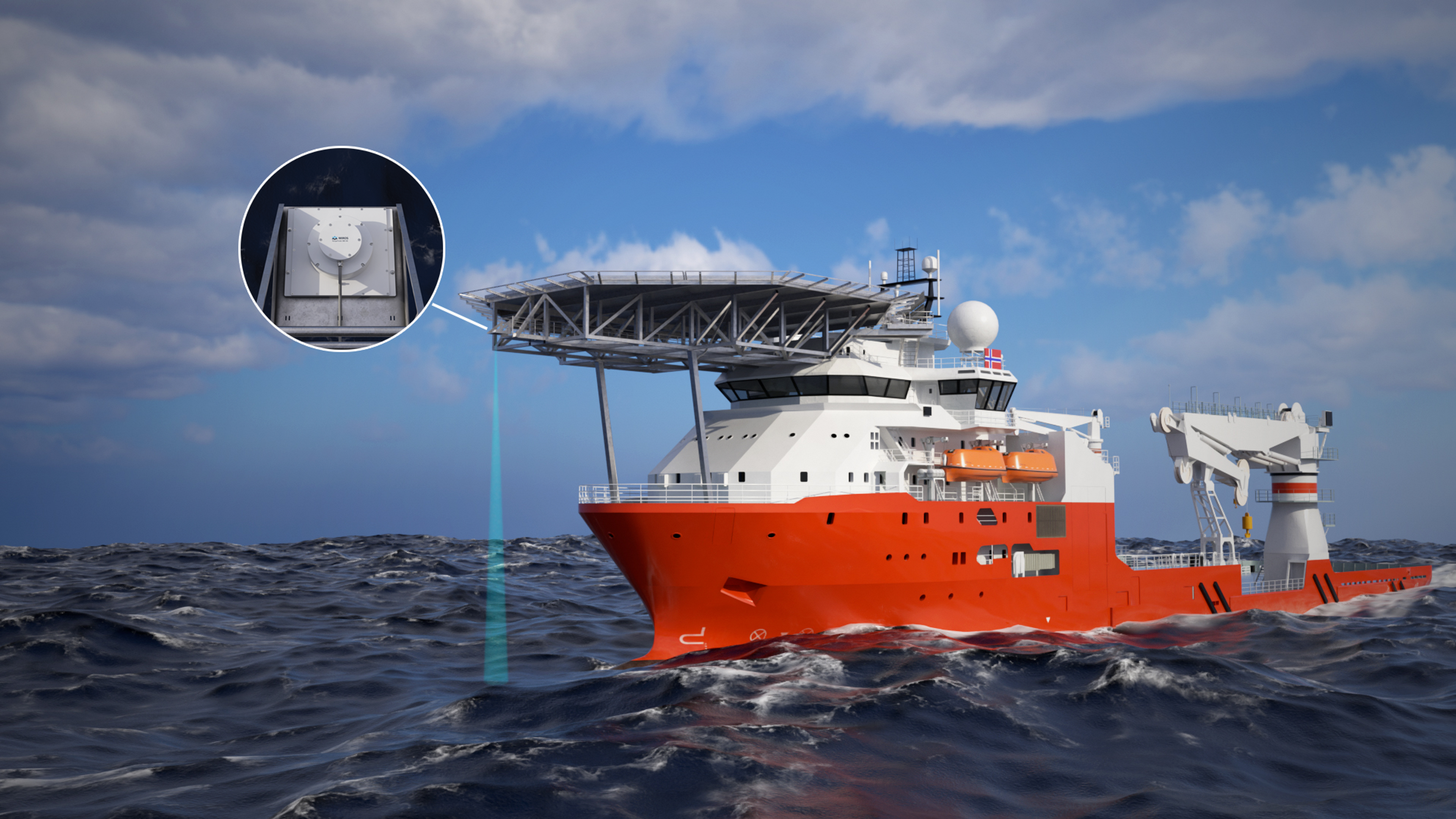

Light Structures has been pioneering the field of ship and marine structural health monitoring with its SENSFIB™ portfolio for more than two decades. The industry’s leading fibre optic monitoring solution for ships and offshore platforms, SENSFIB is based on Fiber Bragg Grating (FBG) technology, which enables unprecedented granularity and visibility into the structural loads acting on a vessel in real-time. It is a key enabler of hybrid digital twin applications and fatigue life extension strategies.

Collaborating with class

SENSFIB is operational on 330 vessels globally and is central to Light Structures’ collaborations with leading class societies. In recent years, this work has expanded to encompass the application of structural hull data within a ship’s digital systems. The 2023 MoU with DNV aimed at integrating SENSFIB’s output into next-generation digital twins for hull integrity management was a key milestone, though the company already had experience of meeting the digitalisation needs of their customers prior to this. Further, Light structures’ SENSFIB Smart Structural Health Monitoring system received ABS SMART(SHM) Tier 3 Product Design Assessment (PDA) certificate in January 2024.

The solution: Integrating motion data expands insight

"If we see different stress patterns under what should be similar sea states, that can indicate that something is wrong."

According to Karianne Pran, CTO of Light Structures, “We use MRUs as part of our hull monitoring systems when motion data are not available from existing ship systems, and when the shipowner wants to facilitate more detailed post-processing of data.” Pran notes that without motion data, interpreting hull stress results in isolation limits the system’s diagnostic value. “It is really useful to be able to understand the weather conditions leading to those stress measurements and how those conditions translate to ship motions. If we see different stress patterns under what should be similar sea states, that can indicate that something is wrong.”

SMART notations need motion data

The demand for data to optimise vessel performance and maintenance applications is driving momentum across the maritime industry: ship owners and operators pursuing SMART notations can deploy integrated monitoring systems like those provided by Light Structures to deliver accurate, contextualised data in real time. And in the context of SENSFIB technologies, MRUs ensure that structural insights are both accurate and actionable. As classification societies formalise digital requirements, MRUs increasingly become foundational components of smart vessel infrastructure supporting enhanced safety, operational efficiency, and environmental sustainability.

Selecting the right MRUs for the job

Light Structures has previously used MRUs from several manufacturers in their structural health monitoring solutions but have standardised on Norwegian Subsea’s systems for specific projects. The decision, Pran explains, came down to a balance of suitability and simplicity. “Norwegian Subsea is lower cost than the high-end units while offering the level of data we need. It also comes with easy communication protocols and in an enclosure that is convenient to fit.”

Operational advantages

Importantly, Norwegian Subsea MRUs do not require recalibration. An advantage that aligns closely with the design ethos of Light Structures. “We can get a Norwegian Subsea unit that retains adequate precision through the planned life of our systems without the shipowner having to go through the cost or hassle of returning the unit to shore for recalibration every few years,” says Pran.

The Outcome: Supporting Broader Maritime Digitalisation Goals

"By pairing motion and stress data, SENSFIB installations equipped with Norwegian Subsea MRUs offer an elevated level of operational insight."

From Norwegian Subsea’s perspective, the collaboration reflects a broader industry transition. “We delivered 20 MRUs last year to a project where the end customer wanted to follow the SMART notation so needed reliable and cost-effective MRUs,” said Chris Ruigrok, Sales manager, Norwegian Subsea. The demand for MRUs in the context of ship digitalisation and SMART notations confirms that the technology is becoming a foundational element of any ship’s digital sensor architecture.

Data That Delivers Operational Value

By pairing motion and stress data, SENSFIB installations equipped with Norwegian Subsea MRUs offer an elevated level of operational insight. This translates into tangible benefits: the ability to detect anomalies earlier, justify maintenance interventions, and support the vessel’s SMART classification objectives through the ability to analyse data from diverse sensors, outside of traditional ‘silos’. The result is that new operational insights and efficiencies can be gained. The SENSFIB system with integrated Norwegian Subsea MRU also aligns with environmental goals. The data provided directly contributes to longer vessel lifespans and as part of a wider SMART environment or digital twin, optimised fuel efficiency.

An approved way forward

The growing endorsement of digital hull monitoring by classification societies, including the recent Approval in Principle from ABS, further validates this approach. As class societies formalise their expectations for integrated sensor ecosystems, the need for high-quality motion data becomes even more pressing. In this context, Norwegian Subsea MRUs serve as a vital enabler, ensuring that structural health monitoring systems not only meet compliance benchmarks but also deliver the consistency and accuracy required to unlock the full potential of ship digitalisation.

About the client

Light Structures

Light Structures AS was founded in 2001 as a spin-off from the Norwegian Defence Research Establishment and is now established as the leading provider of turnkey fiber optic stress and fatigue monitoring systems based on Fiber Bragg Grating (FBG) technology. Light Structures leverages its passion for monitoring to deliver custom solutions based on its SENSFIB(TM) portfolio for the qualification of uncertainties in relation to ship and maritime asset design, safety and operations. More than 300 SENSFIB systems have been installed globally for diverse applications, vessels and customers. Light Structures is headquartered in Oslo and has a growing network of international offices. SENSFIB solutions are sold through a dedicated network of partners and agents worldwide.