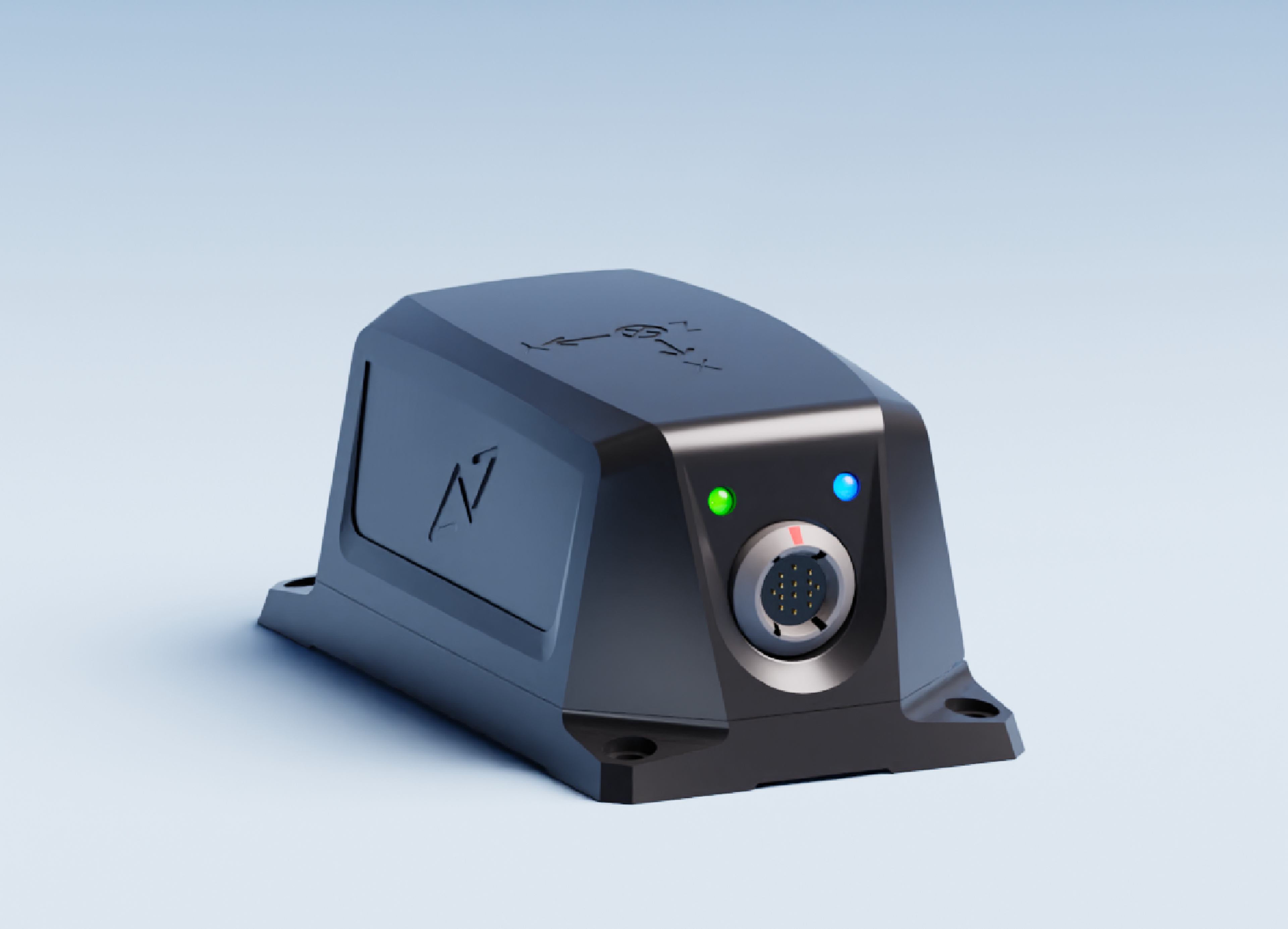

MRU Retrofit Solution

For many applications that depend on an MRU, it can be very costly to perform a re-calibration, repair, or replacement. We have a solution that greatly simplifies this process while saving cost.

Challenge

Many vessels have motion reference units (MRU) installed that need re-calibration and repair. Or maybe they are end-of-life since support and re-calibration services are no longer offered by the original supplier. These older MRUs provide input to many vital systems on board and any fault can create an urgent and critical operational issue for your vessel.

Most MRUs require frequent re-calibration. Re-calibration is a cumbersome process since it involves administration, logistics, installation, configuration, and testing. The overall procedure can be very costly and time consuming. With other MRUs, a normal re-calibration procedure has the following steps.

1. Ship rental / temporary MRU to vessel

2. Install & configure rental / temporary MRU on vessel

3. Ship original MRU to manufacturer for re-calibration or repair

4. Ship calibrated / repaired original MRU back to vessel

5. Install original MRU on vessel again

6. Ship rental / temporary MRU back to manufacturer

Possible customs and export license issues can make this process even more difficult. So, this is not only costly, but the procedure requires 2 installations, rental, 4 shipments, and administration. All this while your vessel is sailing from port to port between countries.

The frequent re-calibration cost and hassle are good reasons to replace old MRUs with Norwegian Subsea MRUs. Even if the old MRUs are not end-of-life yet, there is sound economics in replacing them with our latest generation of MRUs.

So, consider an MRU retrofit solution if your old MRU requires re-calibration or repair.