Ultrabeam Hydrographic enhances high-resolution 3D surveys with Norwegian Subsea Motion Reference Units

Ultrabeam, a specialist in hydrographic survey and underwater inspection, relies heavily on precise motion compensation to ensure accuracy in their 3D mapping projects.

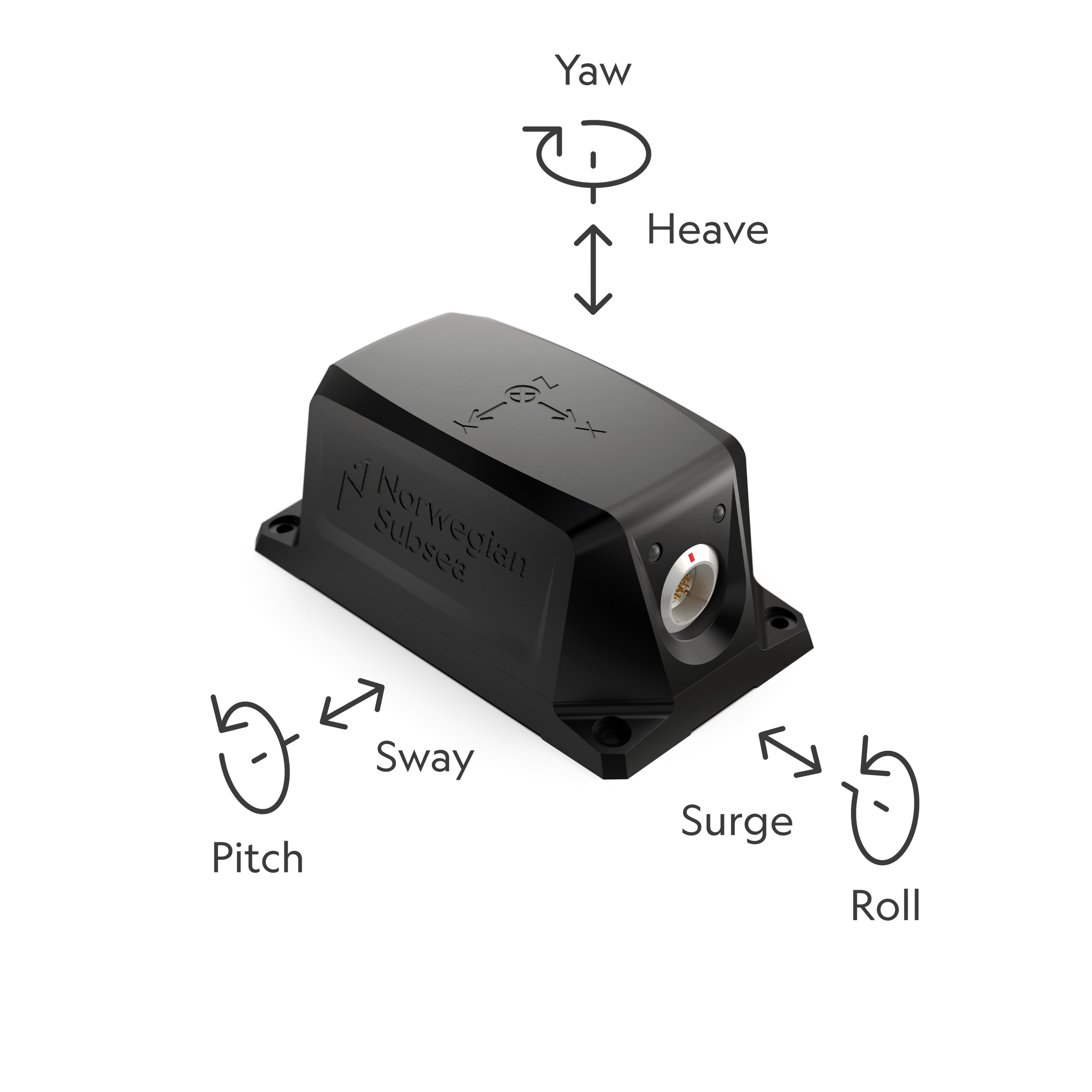

By integrating Norwegian Subsea’s compact, calibration-free Motion Reference Units (MRUs), Ultrabeam has significantly improved its survey data accuracy, while enjoying simplified integration, and enhanced operational efficiency in diverse surveying environments, from bridges, to offshore installations.

About the project

- High-accuracy MRU enhances data precision and reliability

- Compact form-factor supports portability and ease of integration

- Calibration-free operation significantly reduces downtime

- Near-survey grade accuracy without costly RTK setups

The Challenge: Form factor is vital for inland waterways surveying

"Every kilogram matters, and traditional MRUs were simply too heavy…"

High-resolution surveys demand precise motion compensation

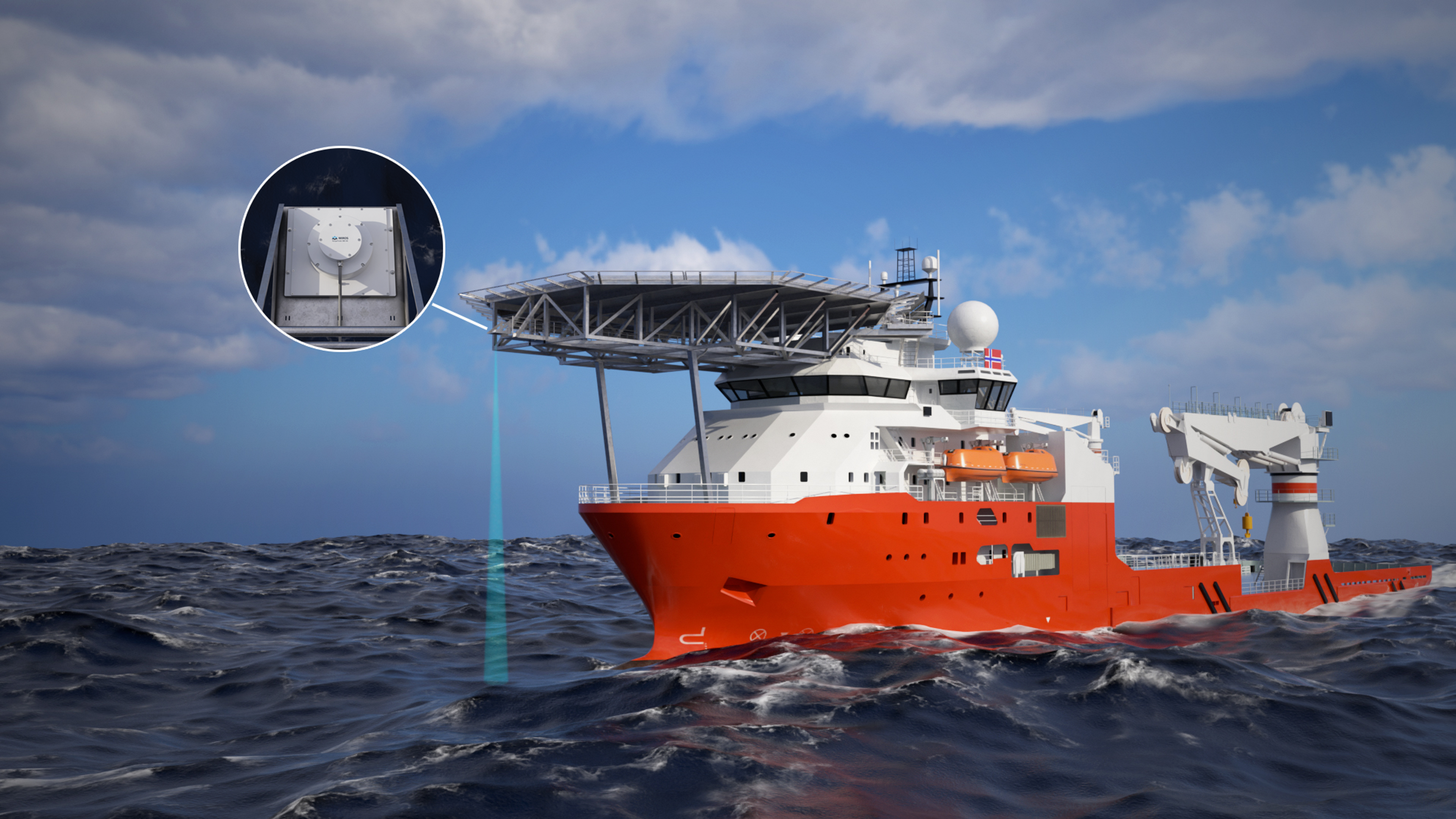

Ultrabeam specialises in high-resolution 3D underwater surveys essential for marine asset inspection. One of their key advantages is the purpose-designed Black Swan, a modular and portable autonomous survey platform for inland and sheltered water use. Black Swan’s multibeam system is on a rotating head and has to acquire incredibly accurate data to maintain the quality of Ultrabeam’s 3D maps, which means precise measurements of motion such as roll, pitch, and heave are critical.

Overcoming the size and weight limitations of available MRUs

Ultrabeam found that conventional Motion Reference Units (MRUs) posed significant integration, portability, and operational challenges for Black Swan. They needed a smaller MRU for integration with the rotating multibeam mount they had developed, and a lighter system to ensure Black Swan could be man-handled easily during fieldwork involving remote or difficult-to-access locations.

According to Gabriel Walton, Senior Product Manager at Ultrabeam, “For many bridge inspections, you might have to carry gear across fields to access remote sites. Every kilogram matters, and traditional MRUs were simply too heavy and cumbersome for our needs.”

The Solution: More portability without reducing performance

"There’s no need for recalibration, significantly reducing our downtime."

Seamless integration, enhanced data quality and ease of use

Norwegian Subsea’s MRUs provided Ultrabeam with the ideal solution: a compact, robust sensor capable of seamless integration into their sonar package and the Black Swan. “We specifically selected Norwegian Subsea MRUs due to their unmatched combination of accuracy, compact form factor, and ease of integration,” explains Walton.

Calibration-free operation eliminates downtime

A crucial advantage of the Norwegian Subsea MRUs is also their calibration-free operation. Once installed and calibrated, they remain consistent over their operational life. Gabriel noted, “We perform an initial calibration just once after installation. After that, there’s no need for recalibration, significantly reducing our downtime.”

Compact form-factor without compromising accuracy

Ultrabeam's field teams often operate in remote areas, making portability essential. The MRU’s compact size and lightweight design perfectly aligned with Ultrabeam’s goal of reducing equipment weight without sacrificing performance. Walton emphasised this advantage, stating, “We built our unmanned vehicle to be as lightweight as possible, and Norwegian Subsea’s MRU offers the accuracy and weight savings we require.”

High-performance MRUs delivering ensuring high-quality data

Integrating Norwegian Subsea MRUs immediately enhanced Ultrabeam’s operational capabilities, delivering high-quality data essential for detailed inspections. “While being the ideal companion in form and fit, the Norwegian Subsea MRU gives us motion compensation performance without needing external corrections,” explained Walton. This has allowed Ultrabeam to operate efficiently even when e.g., RTK infrastructure is unavailable, broadening their operational scope.

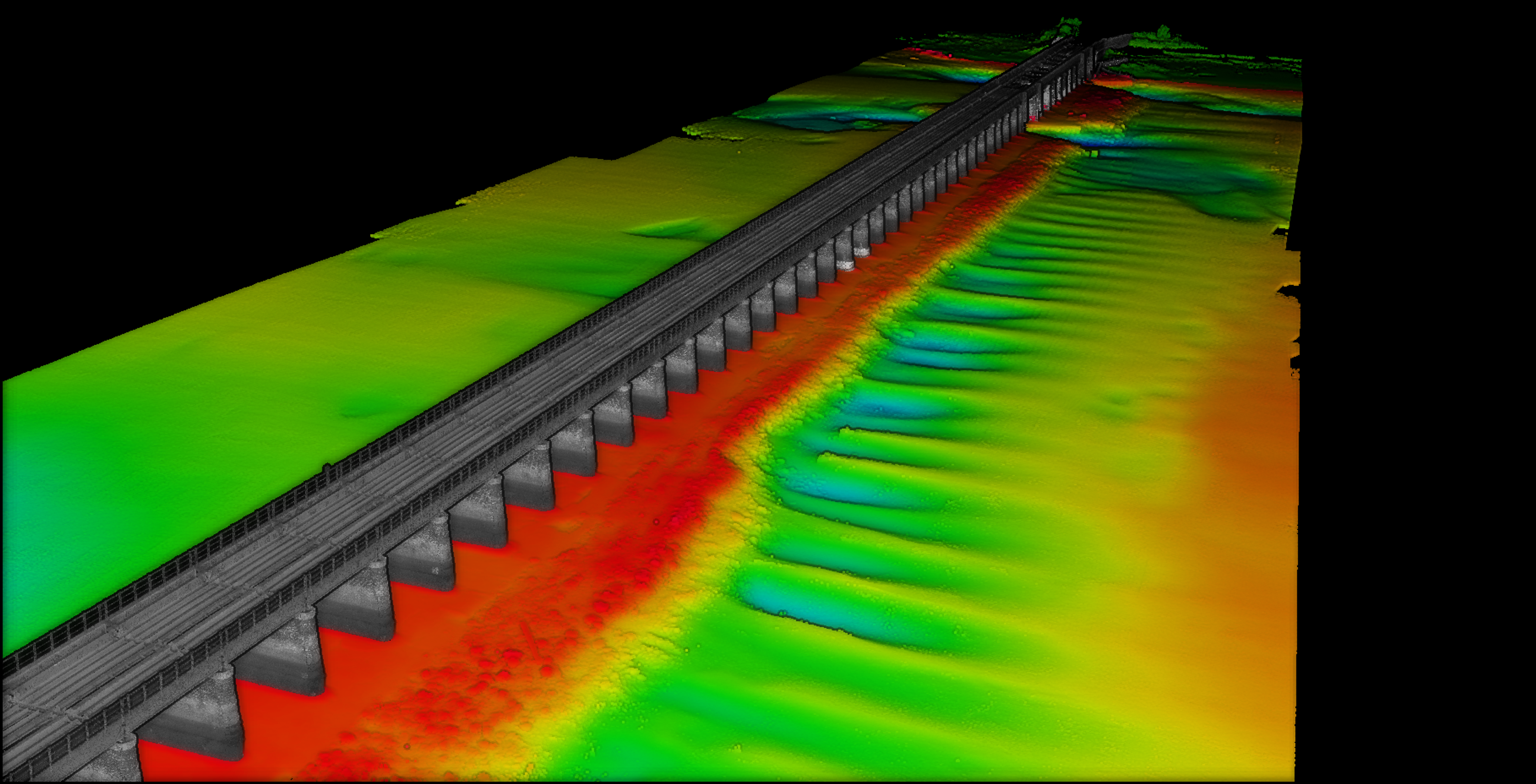

The Impact: Accurate 3D modelling of marine assets

"The accuracy, weight, and form factor of Norwegian Subsea MRUs are unmatched."

Reliable data in challenging environments

With Norwegian Subsea MRUs for multibeam motion compensation, Ultrabeam consistently achieves superior data quality, enabling accurate 3D modelling of the underwater environment near bridges and other marine assets when using Black Swan. “The accuracy, weight, and form factor of Norwegian Subsea MRUs are unmatched. There simply wasn't another product available that delivered everything we needed,” Gabriel noted.

Cost-effective and operationally efficient

The MRU provides Ultrabeam with an ideal balance of portability, cost and performance, lowering overall costs and improving pre-survey logistics. Further, by reducing reliance on external infrastructure and eliminating regular recalibration expenses, Ultrabeam can undertake complex surveys with greater frequency and reliability.

Expanding possibilities in hydrographic surveys

The positive results Ultrabeam experienced through using Norwegian Subsea MRUs have set new benchmarks in operational flexibility and accuracy, positioning the company to expand into more challenging marine survey markets.

About the client

Ultrabeam Hydrographic

Ultrabeam is a leading hydrographic survey company providing high-resolution 3D underwater surveys for marine asset inspection, including ports, bridges, and offshore wind farms. Known for innovation and unmatched data quality, Ultrabeam designs and manufactures bespoke unmanned remotely operated vehicles and integrates cutting-edge sonar and laser technology to deliver detailed data for asset monitoring and maintenance. Their commitment to accuracy and innovation drives their leadership in hydrographic surveying.