ShoreConnection ensures safe landing for thousands of helicopters with Norwegian Subsea Motion Reference Units

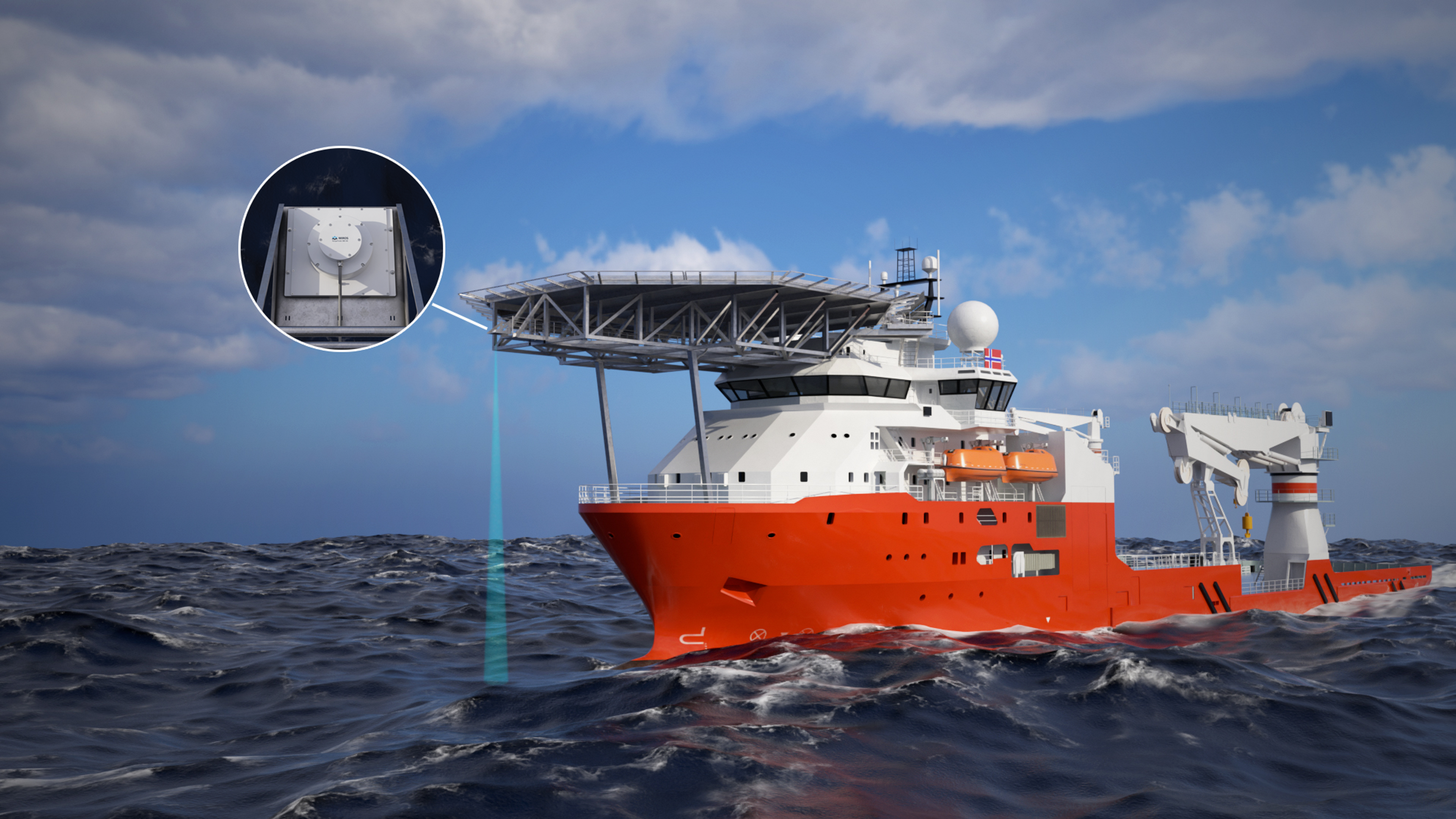

Helideck Motion Monitoring & Weather Data Systems (HMS) provide real-time motion and environmental data essential for flight planning and for pilots to remain in safe control during take off and landing from moving helidecks.

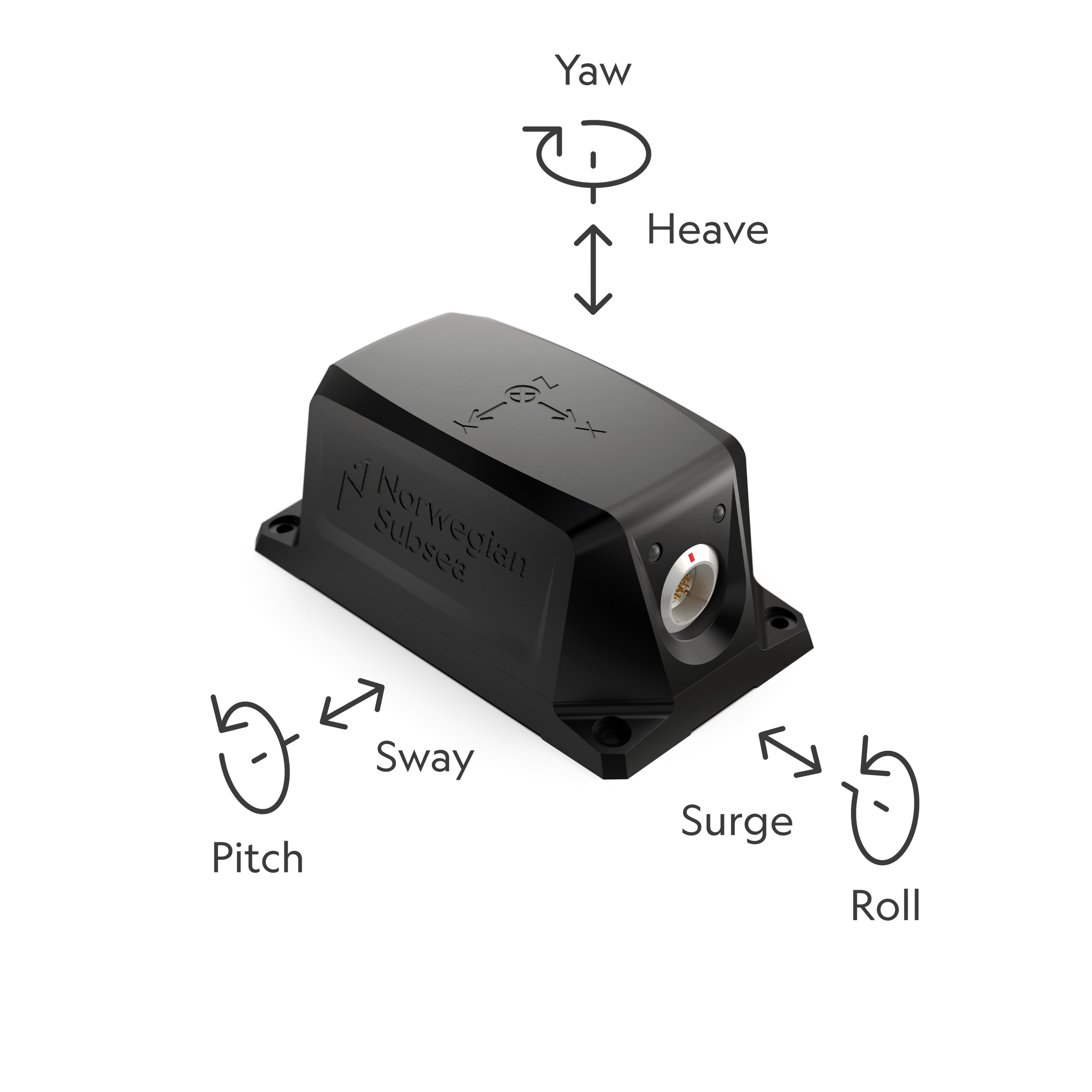

The HMS depends on Motion Reference Units (MRU) installed directly on to the support structure that continuously measure the helideck’s movement. Leading HMS manufacturer ShoreConnection chooses MRUs built by Norwegian Subsea.

About the collaboration

- Accurate motion data essential for safe helicopter operations on moving Helidecks

- Seamless MRU integration and small footprint helps ShoreConnection deliver systems

- Meeting stringent aviation safety standards and new regulatory requirements

- Eliminating the need for costly recalibration reduces potential operational downtime

- IP68 rated and exceptional durability in extreme temperatures, from -40°C to +80°C

The challenge: Ensuring Safe Helideck Operations in Extreme Conditions

"Helideck monitoring systems must now have their own dedicated sensor."

Floating helideck motion such as roll, pitch, and heave must be precisely measured by an Motion Reference Unit (MRU) and reported via a certified Helideck Monitoring System (HMS). Achieving this can be challenging under diverse and extreme sea conditions – including irregular waves and periods of horizontal, lateral and logditudinal acceleration – but the safety of the helicopter crew and passengers depends on it.

Trusted data quality and safety standards

With Norwegian Subsea Motion Reference Units fully integrated, ShoreConnection HMS products are trusted to deliver the data quality and frequency needed, while meeting stringent aviation safety standards that ensure the safety of offshore helicopter operations. They also overcome issues inherent to legacy MRUs from other manufacturers, such as the need to remove the MRU or Inertial Measurment Unit (IMU) and return it to the manufacturer for recalibration every few years. Further, MRU calibration also requires a new MRU commissioning and HMS Data Verification Report. Altogether it’s a process that can potentially cost more than the MRU itself.

Following updated regulations, the capabilities of MRUs used for HMS purposes must match the operational need and required certifications. “Helideck monitoring systems must now have their own dedicated sensor,” said ShoreConnection’s Johnny Rabben.

The solution: High-performance, calibration-free MRUs from Norwegian Subsea

"Installation is easy, and costs are low, especially as there is no need to put the MRUs in a cabinet or external housing."

With their superior accuracy, cost-efficiency, and wide operational range, ShoreConnection is also replacing MRUs/IMUs from other manufacturers with Norwegian Subsea MRUs on a weekly basis. The company’s collaboration with Norwegian Subsea began in earnest around 2018. “They had the accuracy, the temperature range, and the enterprise-level quality we required,” Rabben recalls. Since then, the relationship has deepened, with Norwegian Subsea adapting firmware and configurations to meet specific requirements.

Calibration-free operation: More operational uptime

While field-proven to exceed the data quality an HMS must deliver, one of the most significant advantages of Norwegian Subsea MRUs according to Rabben is their calibration-free operation. Unlike other motion sensors in the HMS segment, they never require recalibration, saving both time and money. This is particularly valuable for clients operating in remote or challenging environments, where the logistical burden of removing the MRU and sending it back for recalibration and re-commissioning can disrupt operations and increase costs.

High performance motion compensation in any marine environment

Their durability across extreme temperatures is also important. Operating seamlessly in a range from -40°C to +80°C and with (IP) 68 Ingress Protection, the MRUs are suitable for the harshest conditions at both ends of the scale. Rabben explains how other MRUs often fail in extreme climates, such as freezing Arctic waters or the intense heat below a metal deck in the tropics and Middle east. In contrast, “Norwegian Subsea MRUs remain stable and functional across its environmental range,” he says.

Changing the installation game: No cabinet, no aircon

The compact design of Norwegian Subsea MRUs for both Safe Area and ATEX Ex also plays a crucial role. Small and lightweight, they are easy to install directly onto steel or aluminium helideck support structure. This simplicity reduces installation costs and allows for greater flexibility in sensor placement. “Installation is easy, and costs are low, especially as there is no need to put the None-Ex or Ex MRUs in an additional environmental protection enclosure,” reports Rabben.

The impact: Reliable Data for Safer Helicopter Landings

"The whole industry is welcoming these MRUs."

ShoreConnection has integrated Norwegian Subsea MRUs into approximately 200 HMS setups so far, with plans to expand this number. The MRUs are critical for clients operating in diverse sectors, where the accuracy and reliability of real-time data continues to ensure pilots can perform within strict operational parameters.

Robust. Reliable. Convenient.

As a leading HMS supplier, ShoreConnection is pushing the boundaries of what helideck monitoring systems can achieve, delivering solutions that are not only robust and reliable but also offering far more convenient installation and maintenance. And as the company continues to deliver certified HMS technology, its collaboration with Norwegian Subsea remains an important factor in client satisfaction globally.

“The whole industry is welcoming these MRUs for sure," continues Rabben. “Our certified HMS, are rapidly becoming the global benchmark and with over 7,000 moving helidecks worldwide, we expect to be working with Norwegian Subsea systems for years to come.”

About the client

ShoreConnection International

For over two decades, ShoreConnection has been at the forefront of offshore monitoring and consultancy, with a primary focus on Helideck Monitoring Systems (HMS). From luxury yachts to FPSOs and oil rigsand fixed platforms, ShoreConnection has earned its place as a leading supplier of HMS technology, and is known for delivering robust, reliable solutions and services for diverse vessels globally. ShoreConnection HMS’ meet the standards set by organisations such as the International Civil Aviation Organization (ICAO) and the UK Civil Aviation Authority (CAA), and have become the benchmarks for safe offshore helicopter operations globally. With stricter certification requirements emerging, the need for dedicated, high-performing sensors has grown. This is where Norwegian Subsea Motion Reference Units (MRUs) have become integral to ShoreConnection’s offering.